Explore our Regular Inlay and Onlay Styles

Inlay and Onlay Lab from China

- 13+ years of dental restoration experience, specializing in precision inlays and onlays

- Compliant with FDA and CE standards for global regulatory approval

- Wide material options: resin, ceramic, zirconia composite

- Factory-direct pricing with 5-year quality warranty

- Both traditional and digital impressions are acceptable

Bestodental Inlay and Onlay Solutions

Bestodental provides precision-engineered inlays and onlays for long-lasting, esthetic restorations that preserve natural tooth structure while restoring function and beauty. Our restorations are crafted from high-performance materials such as SHOFU composite (Japan), IPS E.max (Ivoclar, Liechtenstein), and high-performance Zirconia to ensure superior strength, color stability, and biocompatibility—ideal for clinical excellence in every case.

Our inlays and onlays are custom-made to fit perfectly into the patient’s cavity with minimal preparation, offering seamless integration, durability, and easy daily maintenance. Whether you need composite inlays for cosmetic restorations or E.max onlays for load-bearing areas, we deliver optimized solutions based on your clinical and business needs.

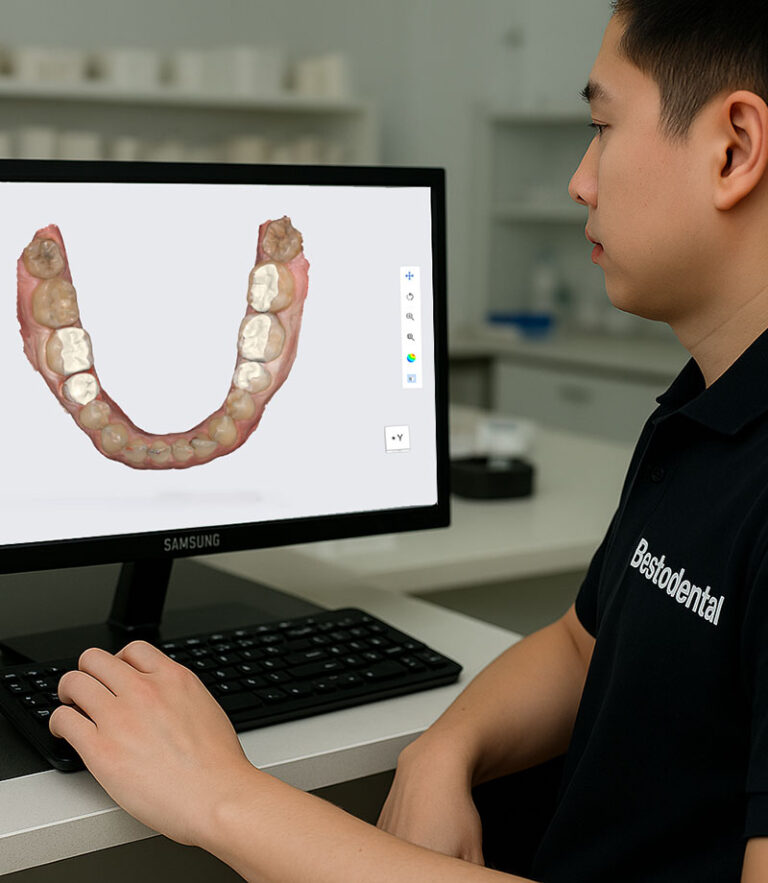

All digital cases will be designed using CAD software to design the tooth shape and other details. Once confirmed, the inlay and onlay will be delivered to you in 4-8 days.

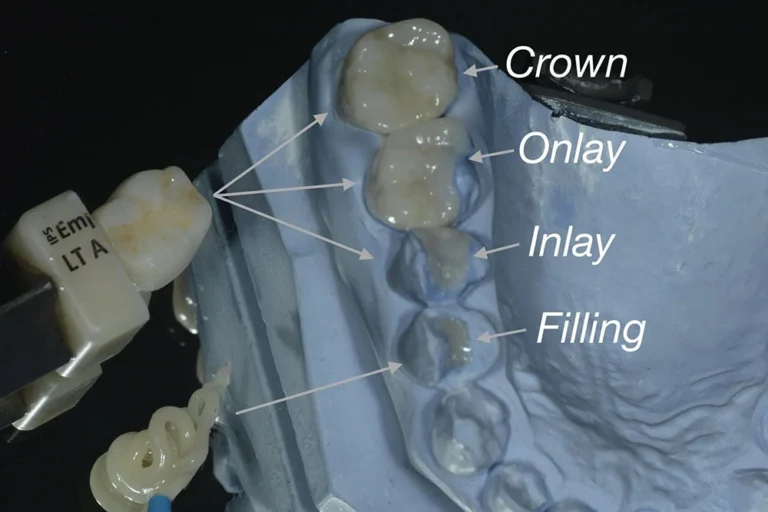

Explore our Regular Inlay and Onlay Styles

Bestodental provides high-quality E.max, Zirconia, Composite, and Metal Inlays for minimally invasive, esthetic restorations. Crafted from premium materials like IPS E.max and SHOFU composite, our inlays offer excellent strength, natural appearance, and precise fit—ideal for restoring decayed or damaged teeth.

Emax Inlay & Onlay

Emax inlays are currently the most popular choice, especially for patients who prioritize aesthetics.

Composite Inlay & Onlay

Composite inlays/onlays are the most affordable treatment option and have the shortest restoration time.

Zirconia Inlay & Onlay

For patients with high strength requirements, zirconia inlays/onlays are a better choice.

Metal Inlay & Onlay

Metal inlays/onlays are typically made from precious metals such as gold or platinum.

Bestodental Inlay and Onlay Features

Full zirconia block (1050~700MPa)

High translucency, Aidite from China (FDA/ CE certified)

Material for E.max inlay

IPS E.max Ingots, Ivoclar, Liechtenstein

Material for composite inlay

SHOFU resin, Japan

Lead time

7 working days

Design software

3Shape

Way of manufacturing

CAD/ CAM

Quality control

100% manual check + digital inspection

Turnaround Time

4-8 days

Send Inquiry

Start Your Next Inlay and Onlay Case with Bestodental

Start your custom Inlay and Onlay solution with Bestodental — certified quality, precise fit, and global delivery.

Precision Design and Milling

BestoDental uses advanced CAD/CAM technology to design and mill every inlay and onlay with micron-level accuracy. Each case is digitally adapted to the cavity prep and occlusal morphology to ensure tight fit and minimal chairside adjustment.

- High-Precision Digital Design (From STL or Model)

- Marginal Gap Accuracy Within ±50μm

- Occlusal Morphology Customized per Opposing Teeth

- Materials: Zirconia / E.MAX / Composite Resin

- Milling from Solid Block or Pre-Shaded Discs

Polishing and Sintering Techniques

To ensure long-term wear resistance and marginal integrity, all inlay and onlay restorations undergo strict surface treatment and controlled sintering cycles. Our polishing and firing protocols are tailored to each material type.

- Multi-Step Pre-Glaze Polishing for Smooth Contact Areas

- Controlled Sintering for Zirconia Strength and Stability

- Resin Polishing with High Gloss for Posterior Use

- Contour Adjustment Before Final Finishing

- Optional Sandblasting for Improved Adhesion

Glazing and Try-In Optimization

Final esthetics and surface texture are enhanced through professional glazing and optional try-in protocols. We ensure that each restoration is ready for seamless clinical delivery, with optional feedback loops for color or contact adjustment.

- Natural Surface Glaze or Matte Finish Options

- Try-In Versions Available on Request (Translucent Resin)

- Final Glaze Firing Under Vacuum for Color Stability

- Anatomical Surface Reproduction for Natural Light Reflection

- Chairside Adjustment Guide Provided Upon Request

Inlay and Onlay Lab FAQs

What materials do you use for inlays and onlays?

We offer SHOFU composite (Japan) and IPS E.max (Ivoclar, Liechtenstein), both FDA/CE certified.

Can you match the color with natural teeth?

Yes, we follow your shade instructions and use digital shade matching for esthetic consistency.

What’s your production time for inlays and onlays?

Standard turnaround is 7 working days after receiving scans or impressions.

Do you accept STL files?

Yes, we support digital workflow. Just send us your STL files—we work with 3Shape, Exocad, etc.

How accurate is the fit?

Our CAD/CAM system ensures ±50μm accuracy for a reliable, passive fit.

How do you ensure quality?

100% quality inspection plus final check by experienced technicians before shipment.

What’s your packing method?

All restorations are individually packed, labeled, and bubble-protected for international shipping.

Can I choose between composite and ceramic?

Of course. We’ll follow your prescription and case requirement.

Get Your Free Inlay and Onlay Quote Now

Bestodental will provide you with the best Inlay and Onlay lab outsourcing service from China