One of the most technologically challenging but clinically rewarding restorative dentistry procedures is the telescopic restoration or the double crown system. They are usually applied in deliverable and hybrid prosthesis to offer better attachment, long-term stability, and predictable load distribution, especially in partially edentulous patients. Nonetheless, they require considerable investment and labor input to manufacture, and they are expensive and demanding in terms of resources due to their large technical threshold, intensive labor, and exact fit requirements.

To the laboratories and clinics that are experiencing increased labor expenses, shortages of technicians, and more demands for consistency, the outsourcing of the telescopic crown and bridge work has become a strategic decision rather than a decision based on cost. China has become one of the most prominent centers of multi-faceted restorative production, providing developed digital processes, scalability, and a large amount of experience in the field of high-precision prostheses. The guide is an effective reference material to international clients on the essence of telescopic restorations, why they are appropriate to outsource, how to handle cases, major risks involved, and how to find the appropriate long-term partner.

1. What Are Telescopic Restorations?

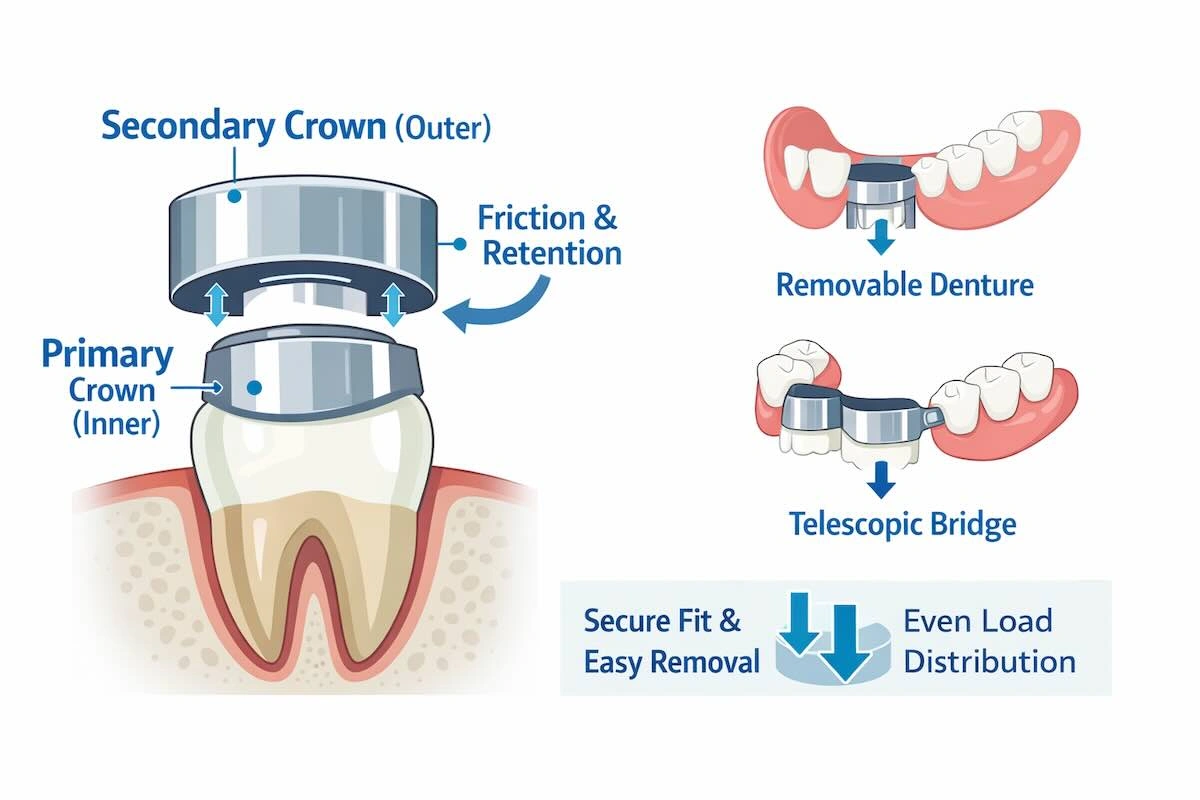

The telescopic restorations are a form of precision system of prostheses, which is designed to hold removable dental prostheses with a two-crown design. The system will have two major elements:

- Primary crown (inner crown): Closely cemented into the prepared abutment tooth or implant.

- Secondary crown (outer crown): This is a component of a removable denture or bridge structure that is fitted accurately over the primary crown.

To hold the two crowns together, friction, conical geometry, or parallel contact against the wall is used. In contrast to the attachments or clasp, telescopic systems distribute the occlusal forces along the length of the abutments, resulting in much less lateral stress and better periodontal protection.

Clinically, telescopic restorations have been preferred because of:

- Patients for whom the abutment teeth are reduced and strategically located.

- Long-span removable bridges

- Cases that need retrievability and access to hygiene.

- Long-term adaptability is required in geriatric patients.

Technically, telescopic restorations require a very high level of tightness. Any slight change in taper angle, surface finishing, or milling precision may jeopardise retention or cause insertion problems. That is the reason why they are also a high-skill product line and why outsourcing is also to be planned.

2. Why Are Telescopic Restorations Suitable for Outsourcing?

The telescopic restorations are especially ideal in outsourcing since they are highly standardized in logic, but labor-intensive to implement. After there is a clear definition of the clinical parameters, a significant part of the fabrication process can be organized with the help of digital workflows.

Major forces that drive outsourcing are:

- High labor content: Manual finishing, polishing, and fitting require a lot of hours from technicians

- Repeatable production logic: Standard taper angles and material systems with standard design protocols make manufacturing scalable

- Digital compatibility: CAD/CAM design, CNC milling, and digital inspection contribute greatly to lowering variability

- Predictable quality benchmarks: Retention force, marginal fit, and the roughness of the surface, which can be measured objectively

To most Western laboratories, the point of outsourcing telescopic restorations to an offshore team is not about substituting local knowledge, but rather redistributing local, competent technicians to high-value-added services like esthetics, case planning, and client communication, and outsourcing repetitive, precision manufacturing to offshore experts.

3. Why Outsource Telescopic Restorations to China?

The combination of structural, technological, and operational benefits has made China a preferred outsourcing destination for telescopic work in the crown and bridge sector.

First, the decisive role is played by the manufacturing scale and specialization. The Chinese dental laboratories that cater to the overseas market frequently have large CAD/CAM centers, which are specialized in high-precision restorations with telescopic facilities. The result of this specialization is cumulative process knowledge and repetitive results.

Second, cost efficiency is not a transient element. Centralized production, high rate of equipment utilization, and vertically integrated workflow are the factors that promote low labor cost and allow competitive pricing without sacrificing material or accuracy level.

Third, there is the issue of digital maturity that stands out. The Chinese export-oriented labs normally deal with:

- Exocad and 3Shape design system

- Five-axis milling machines of high quality

- Digital standardized QC checkpoints

- Complete case data traceability

Lastly, there is the experience and compliance with export. Chinese laboratories have established international prescriptions, turnaround time, and standards of communication, and thus they are more trusted partners to work with in the long term.

4. What Can and Cannot Be Outsourced?

It is very important to understand the scope of outsourcing in order to ensure that the expectations are set realistically, to ensure that there is no misalignment of the laboratories and the clinics, and to ensure that unwarranted friction of operations is avoided. Several clinical and technical variables are considered in telescopic restorations, and not all of the steps can be equally appropriate in offshore production. What is possible and what is impossible to outsource is a very important requirement before things can be expected.

1) Typically Suitable for Outsourcing

- Primary and secondary telescopic crowns (Co-Cr, titanium, zirconia)

- Remote sensing, Digital design of telescopic systems

- CNC milling and sintering

- Removable bridge framework fabrication

- Normal polishing and surface treatment

The similarity between these categories is that they are extremely standardized, digitally-driven, and can be performed with a consistent degree of precision as soon as the clinical parameters have been specified. Consequently, they play well in a centralized production setting where the CAD/CAM workflows and quality control are well developed.

2) Less Suitable or Not Recommended

- Adjustments that should be made by the chairside and need to be provided by the clinical side

- Atypical or experimental taper designs

- Incomplete clinical data cases

- Restorations that are urgent or same-day

Such cases are normally based on real-time clinical input, subjective judgment, or time-related decision-making. The effort to outsource them adds more uncertainty and risk recreation, and in many cases, it neutralizes the benefits of outsourcing that are supposed to be provided to the operations.

Specific delimiting of the boundaries goes beyond risk containment; it creates both common ground and helps stabilize the workflow as well as builds trust between the outsourcing lab and the clinical customer.

5. Step-by-Step Outsourcing Telescopic Restoration Workflow

Successful outsourcing of telescopic restoration is based on a structured and well-defined workflow. Telescopic systems also present a significant difference to conventional crown and bridge systems that consist of several interdependent components, and minor variations may add up to failure. A workflow that is developed in a step-by-step manner enhances technical precision as well as offers transparency and control to both the outsourcing laboratory and the clinical customer.

Step 1: Case Submission

The process of outsourcing starts with the proper and complete submission of a case. In telescopic restorations, the success of downstream is dictated by the quality of upstream data. Any uncertainties at this point will be increased during production and assembly.

Key requirements include:

- STL files or well-articulated physical models

- Specification includes taper angle, material of primary and secondary crowns, and expectations of the retention force (light, medium, strong)

Step 2: Design Review

After the case, the outsourcing laboratory performs a comprehensive digital design review. This step aims to confirm the presence of a functional telescopic system in the information one has put in it before the actual material is cut.

Some of the important points that can be raised in this critical review are:

- Confirmation of the mutual path of insertion of abutments

- Parallelism or consistency of conicity between crowns

- Undercut identification and clearance assessment

- Space evaluation of secondary crowns and frameworks

This measure will serve as a technical gateway to detect possible problems as early as possible, when fixing them is cost-effective and risk-averse.

Step 3: Client Approval

Design intent needs to be agreed upon between the two parties before the commencement of manufacturing. Client approval makes responsibility real and avoids post-delivery subjective conflicts.

Approval normally comprises:

- 3D previews or screenshots of the telescopic structure

- Checking of taper angles, margins, and positioning of frameworks

- The approval or digital signature before production

Clarity of approval ensures the design decisions are turned into agreed technical requirements.

Step 4: Manufacturing

Digital planning is a tangible fact in manufacturing. Process and precision must be of the utmost importance, with micron-level differences potentially introducing distortion to retention and insertion.

The scope of manufacturing typically includes:

- Primary and secondary crowns are CNC-milled

- Depending on the material, controlled sintering, casting, or post-processing is used

- Isolation of the inner and outer production of the crown to remain accurate

More advanced outsourcing labs are dependent on a consistent machine calibration and material-specific procedures to guarantee uniform results.

Step 5: Finishing

Clinical usability closes the gap between mechanical accuracy and finishing. This phase demands human hands who are proficient, particularly when it comes to telescopic systems.

Key finishing tasks include:

- Polishing and refining the surfaces of contact manually

- Manual regulation of friction and retention force

- Removal of acute edges or points of resistance to insertion

The most frequent cause of retention inconsistency and difficulties in insertion is improper finishing.

Step 6: Quality Control

Quality control is not a one-point process but an operational check. In the case of telescopic restorations, QC emphasizes performance but not appearance.

Common QC processes are:

- Checking of primary and secondary crowns

- Inspection of the design parameters of tolerance

- Functional test of insertion and removal

- Checks on the consistency of the retention force

This step helps in making sure that the system works as required and not as produced.

Step 7: Packaging and Shipping

The last step is what makes sure that all the previous work is received in the same form and can be traced. The packaging may spoil the perfect production.

Standard practices include:

- Filling to avoid deformation or damage on the surface

- Labeling of primary and secondary components

- Insertion of documentation and reference cases

- International delivery tracking

This is a structured workflow process that guarantees transparency, accountability, and repeatability- three key attributes of outsourcing high precision telescopic restorations at the international level.

6. Turnaround Time: What to Expect and How It Is Structured

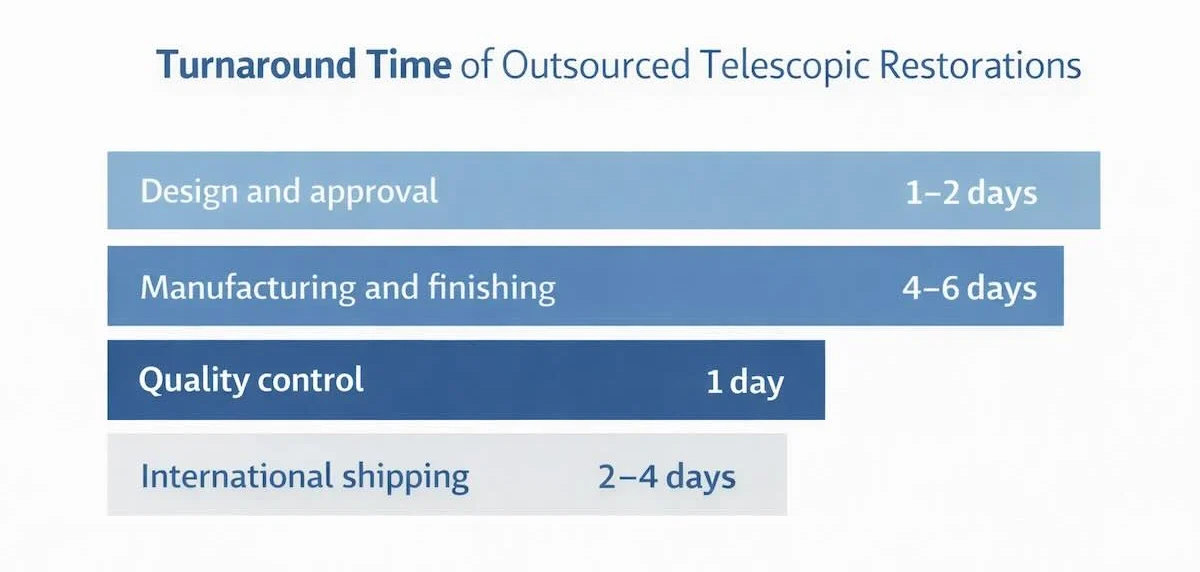

One of the most important factors when outsourcing telescopic restorations is turnaround time, which has a direct impact on clinical scheduling, communication with patients, and the management of a case in general. Telescopic systems have several steps that are interdependent as opposed to standard crown and bridge work, so timeline transparency is much more crucial than headline speed. Most of the mature outsourcing processes will have a turnaround time of between 7 and 12 working days, depending on the complexity of the case, selection of material, and the mode of shipping products internationally.

Normative timeline breakdown consists of:

(1) Design and approval: 1-2 days

This step includes the digital case examination, telescopic design, and confirmation to the client. The delays at this stage are usually due to failure to complete prescriptions or slow feedback to approve, instead of laboratory capacity.

(2) Production and completion: 4-6 days

This is the main line of production, which comprises CNC milling, sintering or casting, and manual finishing. Cases that have multiple abutments, mixed materials, or reduced retention tolerances can be biased towards the upper end of this range.

(3) Quality control: 1 day

Quality control is done by specializing in proper fit, retention, and functional insertion during shipment. This is one area where the suppliers cannot afford to hurry on because a lack of QC or undercutting it is one of the most frequent causes of remakes.

(4) Shipping to different countries: 2-4 days

Transit time is determined by the courier selection, the country of delivery, and the clearance. Export-driven labs usually collaborate with their stable logistics partners in order to reduce variability.

It is worth pointing out that realistic turnaround promises are about the maturity of the processes and not the speed promises. Reliable outsourcing partners give timelines that rely on validated workflow and buffer capacity, and this allows the labs and clinics to plan their treatments and be assured of delivery, rather than using the over-positive delivery estimates.

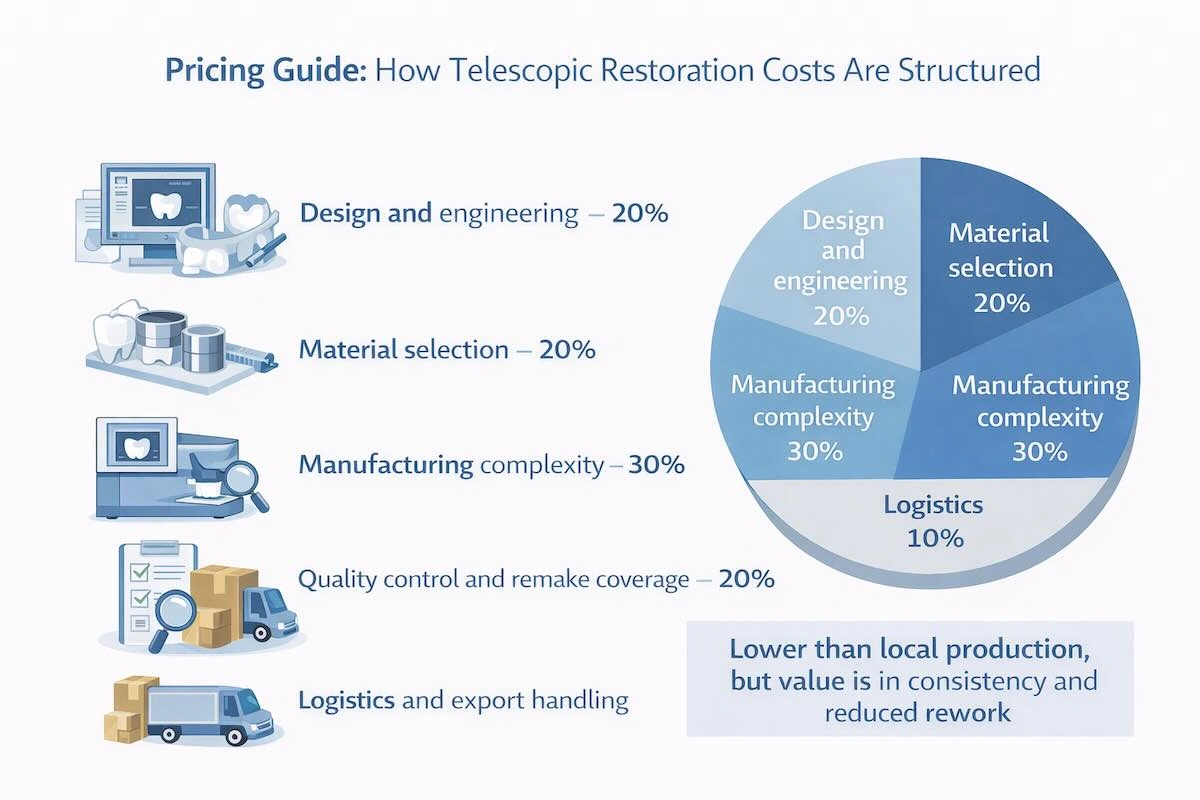

7. Pricing Guide: How Telescopic Restoration Costs Are Structured

Pricing is the second important issue that is often considered after turnaround time when outsourcing telescopic restorations. But again, unlike the regular crown and bridge work, the telescopic systems cannot be considered entirely on unit cost. Their costing framework is an indication of the various interconnected technical and operational issues, which have a direct impact on consistency and remake risk.

The common price elements are:

- Design and engineering: Design work, telescopic-specific design Work such as the design of insertion paths, taper control, and design validation.

- Material selection: The prices differ between Co-Cr, titanium, zirconia, and mixed-material systems, which involve the steps of different processing stages.

- Manufacturing complexity: Difficulty in the case, the number of abutments, and tolerance needs affect the machining time and finishing effort.

- Remake coverage and quality control: Trustworthy suppliers establish QC and impose remake responsibility into their prices, as opposed to them being exceptions.

- Export management and logistics: The delivered cost includes international packaging, international documentation, and international shipping.

Practically, the off-shoring of telescopic restorations to China would in many cases provide 30 50 percent cost reduction over domestic manufacturing. The main value, though, is not only the low prices but also the predictability of the workflow, minimizing remakes, and ensuring the steady delivery schedule.

Pricing has always to be considered along with the turnaround time and depth of quality control. Questions that are not realistic can signify tightened procedures and augmented downstream hazard.

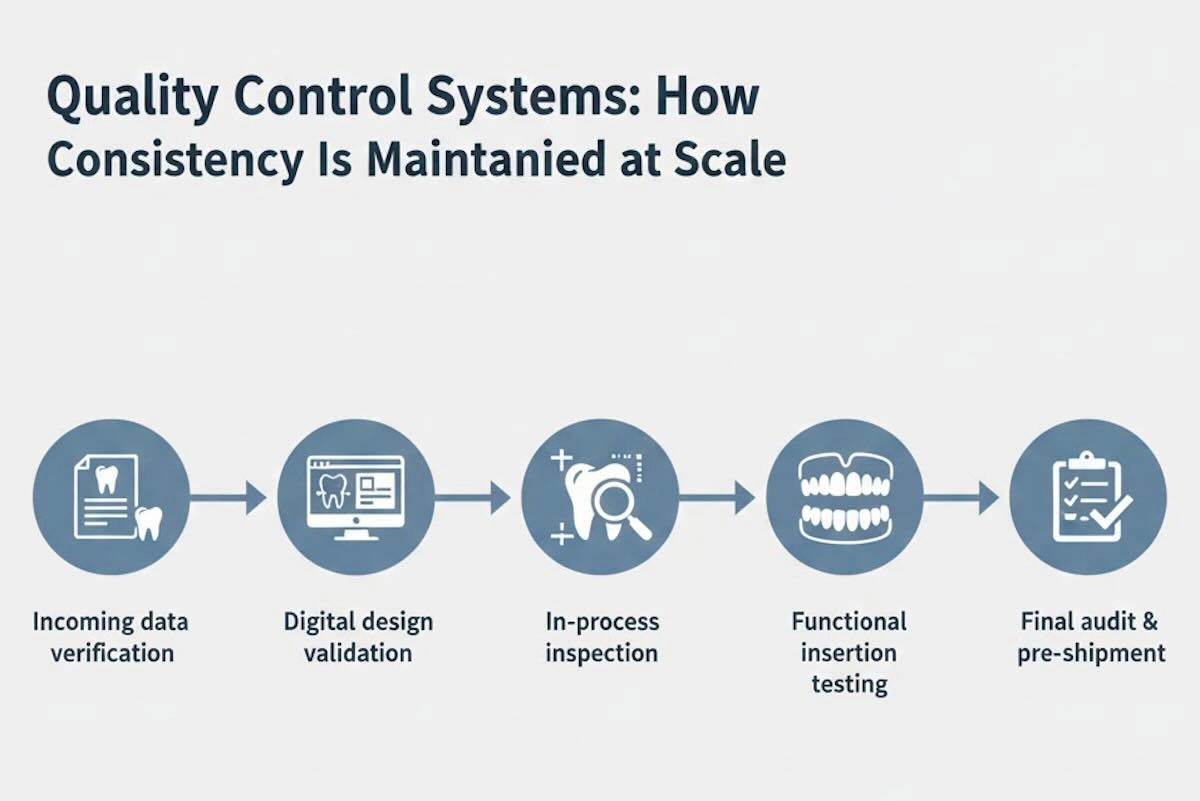

8. Quality Control Systems: How Consistency Is Maintained at Scale

The most important consideration of the telescopic restoration outsourcing is the quality control, where even slight shifts in fitting or retention can result in clinical failure. In contrast to the esthetic restorations, telescopic systems need to be judged primarily by functional performance and not visual appearance. This is the reason why effective outsourcing is based on multi-stage QC systems and not a final inspection.

A fully-developed QC system will usually comprise:

- Incoming data verification: The case files are checked to be complete, to have an insertion path, and prescription clarity before the commencement of the design.

- Digital design validation: Checks on taper angles, parallelism, and clearance against predetermined technical standards are made before manufacturing.

- In-process inspection: During the production process, milling precision, material integrity, and intermediate fit are checked to avoid the buildup of errors.

- Functional testing: Primary and secondary crowns are tested with insertion, removal, and retention performance tests as opposed to visual checking only.

- Last audit and pre-shipment authorization: All cases are checked against the acceptance requirements after completion, and then packed and sent out.

Such a stratified QC strategy makes sure that problems are spotted timel mannery, addressed effectively, and they are stopped at the clinical level. The issue of quality in the telescopic restoration outsourcing is not an outcome of a single inspection point, but rather the outcome of a process of control that is repeated in every case.

9. Communication Requirements to Avoid Remakes

Communication in general can be more significant than all the technical steps in terms of reducing remakes in tele-scopic restoration outsourcing. Laboratories and clinics should have distinct and systematic guidelines to be followed at the beginning to guarantee predictable results. Some of the requirements are:

- Complete prescriptions: All the information about the case must be of excellent quality and detailed because incomplete and unclear submissions are the foremost reason for misunderstanding.

- Taper and retention specifications: The important design specifications should be communicated and agreed upon before the commencement of production.

- Naming conventions: Naming conventions will mean the same file and component names will be used across the design, milling, and assembly phases to avoid confusion.

- Documentation of design alterations: The appropriate changes or clarification must be documented to form an audit trail and avoid speculation.

With such systematic communication procedures, outsourcing will no longer be an unpredictable variable, but a structured and repeatable process. These practices are a major step towards minimizing the risk of remakes and enhancing a smoother collaboration between the laboratory and the clinical client.

10. Risks and Mitigation Strategies for Telescopic Restoration Outsourcing

There are inherent risks in the outsourcing of telescopic restorations since it is a high-precision and highly dependent process on design, manufacturing, and clinical requirements. The awareness of these risks and the knowledge of the reasons why they occur allow laboratories and clinics to implement systematic mitigation measures and ensure the predictability of the final results.

| Common Risks | Why It Happens | Mitigation Strategies |

| Retention mismatch | Minor deviations in taper angles, surface finish, or milling tolerances | Conduct pilot cases to validate taper angles and retention design before full-scale production |

| Insertion difficulty | Poor communication of clinical conditions or incomplete adjustment instructions | Establish clear acceptance criteria for fit and retention, confirmed in writing before manufacturing |

| Data inconsistency | Incomplete, ambiguous, or incorrectly formatted case submissions | Implement documented QC checkpoints at every stage, from case submission to pre-shipment inspection |

Supplier maturity is indicated in professional risk management. Outsourcing can be known as a controllable, repeatable process by becoming informed of the causes of risk and implementing systematic mitigation systems, instead of being considered an uncertain or unpredictable process. This method guarantees the clinical reliability and the success of further cooperation.

11. How to Choose the Right Outsourcing Partner for Telescopic Restorations

The choice of the correct outsourcing company is key to successful quality consistency and reliable delivery of telescopic restorations. A formal assessment procedure aids the labs and clinics in reducing the risk and also ensures that the selected supplier is able to act as a dependable continuation of their internal manufacturing.

In assessing suppliers, consideration can be made based on the following:

- Telescopic systems experience: Prior practical experience indicates that the supplier is familiar with special tolerances and other functional needs of the designs with both crowns.

- Digital design skills: Excellent CAD / CAM skills will provide accuracy in virtual planning and minimize the chances of remakes.

- QC transparency: The multi-stage quality control is well documented, assuring that every case is up to specified acceptance standards.

- Responsiveness to communication: Delays and misunderstandings can be avoided through quick and organized responses to inquiries or clarifications.

- Long-term relationship attitude: Suppliers who believe that partnerships are better than one-time purchases are more apt to sustain uniform processes and can easily adjust to changes in clinical requirements.

Having experience working with exporting and telescopic workflows, Bestodental integrates fully developed digital design systems, open QC procedures, and organized communication systems. They do not just do transactional manufacturing: they will offer the end-to-end support, which includes scrutinizing the case and ensuring its design, tracking delivery, and offering post-insertion advice. The selection of such a partner as Bestodental enables the laboratories and clinics to take advantage of the global manufacturing experience and still retain control over key clinical outcomes, ensuring that the partnership relationships are stable and can be scaled according to the long-term growth goals.

12. Who Should and Should Not Outsource Telescopic Restorations

Outsourcing of telescopic restorations will not equally be beneficial in every laboratory or clinic. The operational requirements, technical capability, and case volume should be evaluated before arriving at a decision to outsource in order to establish whether outsourcing will be in line with the strategic objectives. Knowledge of the right fit will allow exploiting the benefits of precision production to the greatest extent and reducing possible obstacles.

1) Suitable Candidates to Outsource

- Small, mid-sized labs: These facilities are capable of increasing production and decreasing the effects of labor bottlenecks without having to spend a lot of money on expensive equipment.

- Clinics that have large removable case volumes: Outsourcing provides clinicians with a chance to work on more complicated cases effectively without compromising the quality.

- Labs that go digital: Labs that have already implemented CAD/CAM systems are integrated with the external design and production processes.

2) Less Suitable Candidates

- Ultra-custom one-off cases: Ultra-custom or experimental designs usually demand instant feedback at the chairside, and are challenging to standardize.

- Practices induced by emergencies: The cases that require turnaround on the same day cannot fit offshore production schedules.

- Clinics with insufficient standard data submission: Incomplete or non-uniform case files put the risk of remakes and communication errors in the case of incomplete cases.

The outsourcing process must be seen as the extension of in-house facilities as opposed to a universal answer. In the case of the appropriate laboratories and clinics, it would offer scalable manufacturing, quality assurance, and access to expertise. The advantages might not be as great to those who either lack the necessary level of workflow standardization or do not need this in high volume, and in-house or other solutions might still be the best option.

13. Outsourcing Telescopic Restoration FAQs

In the case of outsourcing telescopic restoration, there are numerous operational, technical, and strategic uncertainties that many laboratories and clinics have explained. The questions below will cover the most common questions and offer practical advice, which will be based on the best practices and industry standards.

Q1: Is the outsourcing of zirconia telescopic crowns possible?

Yes. Zirconia crowns can be outsourced without failure; however, taper angles, surface finish, and insertion fit have to be handled with great care. Digital designs cannot be verified by suppliers, nor are pilot test insertions possible to verify retention to clinical specifications.

Q2: What is the control of the retention force of outsourcing?

Three methods of retention primarily involve taper geometry, surface finish, and functional testing. Digital design checking, milling precision, and the testing of insertion are all standardized procedures to ensure that the secondary crown clips the primary crown with neither too much friction nor too much looseness.

Q3: What is the average remake or amendment policy?

Remake policies are different depending on the supplier and must be specified in the contract. Organized QC checkpoints, acceptance requirements, and a clear description of the responsibilities are provided in professional laboratories to minimize disputes and have all the deviations resolved within the appropriate time.

Q4: What are some of the ways of reducing communication errors during the outsourcing of complex telescopic cases?

Formal protocols of communication are imperative. Full prescriptions, format names, clear taper and retention requirements, and written notification of design changes are all beneficial in reducing the amount of confusion. Most of the suppliers with experience are sharing digital platforms that trace all the case steps and communication logs.

Q5: What can be done to keep clinics consistent on multiple cases that are outsourced?

The consistency is ensured via the recurring use of the standardized digital processes, multi-level quality management, and work with proven suppliers, ensuring the documentation of all operations. The long-term arrangements enable suppliers to know some clients’ preferences, material standard and functional tolerances, thus minimizing variability.

14. Conclusion

The telescopic crown and bridge restorations are highly precision-based, system-based prosthetics and very strict on the design, material use, and workflow processes. These restorations are no longer merely a cost-saving step in outsourcing; when done with proper care, it turns out to be a strategic expansion of in-house laboratory functions or clinic.

The selection of the appropriate outsourcing partner is crucial in order to achieve these benefits. Bestodental, having positive experience of exports and having specific telescopic working processes and strong QC procedures, offers not only expertise, but also operational integrity. A long-term relationship with those partners can enable laboratories and clinics to scale production, handle complex removable cases effectively, and maintain reliability in the quality of multiple cases. Finally, in the case where outsourcing is directed by knowledge, discipline, and regulated procedures, telescopic restorations can be a reliable, scalable service that reinforces clinical performance as well as business expansion.