With the ever increasing demand in the global dental and the continued mounting cost pressures, there is an increasing number of dental labs and dental clinics reconsidering the production methods and locations of removable restorations. Of all the types of prosthetics, removable dentures have been one of the most labor-intensive, technique-sensitive, and marginally challenging products. This has seen most foreign laboratories consider an outsourcing solution as a viable strategy, especially to China, where the dental manufacturing ecosystems have grown tremendously in the last 20 years.

The guide will be aimed at offering a detailed, practical, and decision-based overview of how to effectively outsource removable restorations in China. This article will be useful to you whether you are the owner of a dental laboratory, a clinic manager, or even a procurement professional, in that you understand the product fundamentals, the rationale behind outsourcing, the workflows, the risks, and the best practices, so that you can make informed, controlled, and sustainable decisions on outsourcing.

1. What Are Removable Restorations?

Removable restorations are dental implants that are made as a substitute for missing teeth but can be removed and reinserted by the patients. They rely upon mechanical retention and accurate fit as opposed to permanent cementation, as seen in fixed restorations like crowns and bridges.

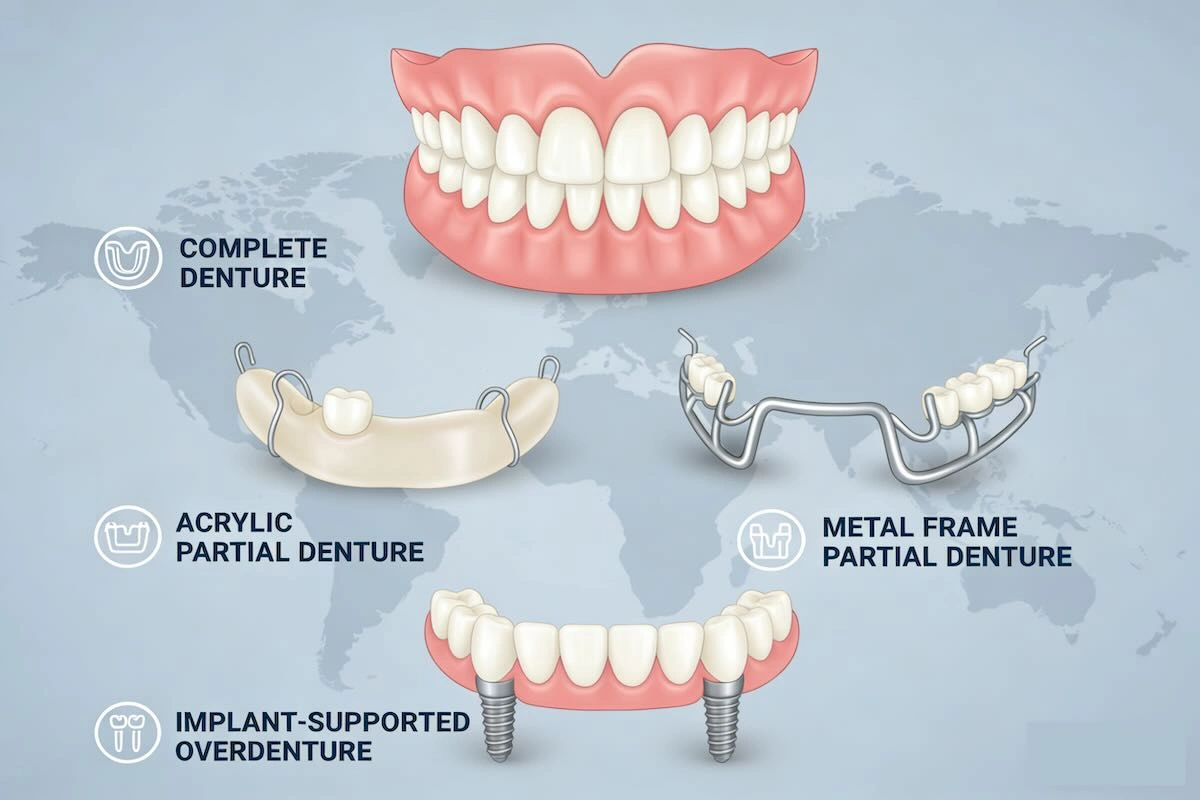

Widely used forms of removable restorations are:

- Full dentures for fully edentulous patients

- Partial dentures in situations where there are some natural teeth

- Dentures that are manufactured using thermoplastics

- Retention and stability of implant-supported overdentures

The restorations are commonly made of acrylic resins to form the denture base, prefabricated denture teeth, and (where necessary) metal frameworks like cobalt-chromium. Digital design and scanning are being used more and more often in modern laboratories to supplement traditional ways of fabrication.

Removable restorations, which are used clinically, provide the patient with basic oral functions of chewing, speaking, and facial support, and are also a cost-effective intervention in patients who are not candidates for fixed or implant-only therapies. In terms of production, though, they are very labor-intensive, with several manual procedures and close attention from the technicians. This clinical significance and production intensity combination predetermines the context within which outsourcing is going to be discussed further.

2. Why Are Removable Restorations Suitable for Outsourcing?

Removable restorations are specifically very favorable towards outsourcing, in terms of repetitive production logic, predictable clinical needs, and richness of labor. Dentures have a standardized design and material system in comparison to highly individualized esthetic restorations, and can be more easily scaled to specialized production teams.

Cost efficiency is one of the main reasons why one outsources. Denture creation requires a great deal of manual labor, such as wax preparation, positioning of teeth, flasking, finishing, and polishing, which all demand the assistance of competent technicians. In the expensive areas, labor costs tend to eat away at the margins, particularly those markets that are insurance-based or price-sensitive.

Moreover, the volumes of demand for removable restorations are relatively stable. The aging population, edentulous patients, and maintenance/ replacement cases make the case flow constant, which is very congruent with the models of outsourcing based on batch production and process optimization.

The outsourcing also provides the ability for the local laboratories and clinics to reassign the internal resources. When production-intensive denture work moves offshore, the in-house teams will be able to concentrate on high-value services, including case planning, digital design, customer service, and clinical collaboration- activities that help build strong ties and differentiate with clients.

3. Why Outsource Removable Restorations to China?

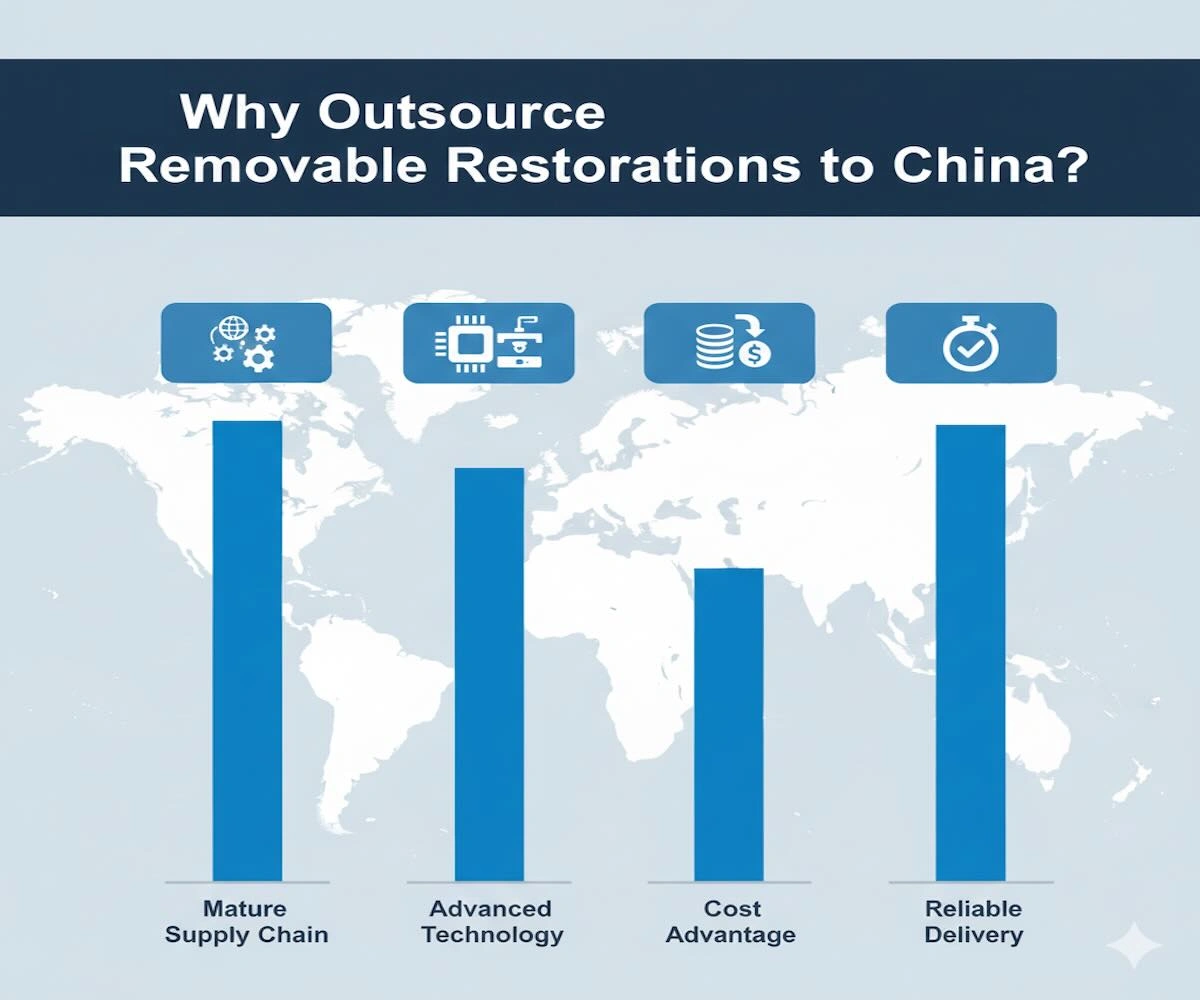

In addition to the overall advantages of outsourcing, China has emerged as a destination of removable restoration production thanks to a set of structural, operational, and market-based factors.

(1) Established Dental Production System

China has built a proper dental production ecology over the last 20 years. High-volume removable denture cases can be handled consistently with large-scale dental laboratories, special removable teams, and standardized production workflows.

(2) Cost Structure Benefit without Basics Sacrifice

China has a more competitive structure of labor costs in comparison with Western markets. Removable restorations are very labor-intensive, and so this cost benefit is of major influence without altering the basic materials or clinical design principles.

(3) Experience International Markets

Numerous dental laboratories in China have been in the business of serving customers in North America, Europe, and Australia for a long period. This export experience implies that they are conversant with international prescriptions, documentation, and general clinical expectations.

(4) Enhancing Turnaround Reliability and Logistics

Many international shipping and case management systems would be optimized, and outsourcing to China would no longer be associated with unpredictable delivery times. Turnaround times can be kept at a constant and manageable level when the workflows are well managed.

4. What Can Be Outsourced? And What Cannot?

The scope of the outsourcing should be clearly understood to prevent the incompatibility of expectations and operational risk. In the case of removable restorations, the establishment of the ability limits in the initial phases is one of the most important elements of the collaboration.

1) What Can Be Outsourced

- Complete dentures: Conventional full-arch removable restorations with consistent clinical history and repeatable logic of fabrication.

- Acrylic partial dentures: Cases where there are definite design needs and retention structures that are predictable.

- Metal framework partial dentures: The incorporation of cobalt-chromium structures that were made using either the traditional or CAD process.

- Flexible dentures: Thermoplastic semi-finished products that follow standardized processing systems and materials.

- Implant-supported overdentures: Reviable prostheses with well-established implant sites and fixation mechanisms.

- Digitally supported workflows: These include digital denture systems and CAD-based architecture built in conventional manufacturing.

2) What Should Not Be Outsourced

- Highly complex bite reconstruction cases: Cases where clinical adjustment is very extensive or where occlusal verification has to be continuous.

- Immediate dentures requiring same-day delivery: Cases that are time sensitive and require chairside changes

- Cases with unstable or inaccurate impressions: In outsourced production, poor clinical input is a major cause of remake risk.

- Cases requiring frequent chairside feedback: Geographic distance restricts rapid iteration and real-time adjustment.

Practically, the most effective approach that laboratories use to maximize their performance is to outsource standardized, repeatable, and removable cases and retain highly complex or time-sensitive work internally.

5. Step-by-Step Workflow for Outsourcing Removable Dentures

The success of removable denture outsourcing is based on the existence of a well-defined workflow. It also offers predictability, quality management, and eliminates redundancy in remakes. In reality, the efficient outsourcing workflow may be subdivided into the following steps.

Step 1: Submission and Documentation of the Case

The process of work starts with a full and proper submission of cases. This normally incorporates physical impressions or digital scans, written prescriptions, bite records, shade information, and reference photos. Missing or incomplete submissions at this point are the most prevalent cause of a downstream problem.

Step 2: Design and Technical Review

Upon getting the case, the outsourcing laboratory will then carry out a technical review that may determine the risks that may arise regarding fit, occlusion, or design feasibility. In removable restorations, this is an important step to be taken, since clarification in the early stages of production will prevent remakes in later production.

Step 3: Design Confirmation or Try-In Approval

In most instances, primarily partial dentures or complete dentures that have esthetic needs, design validation is given by using digital arrangements or try-in previews. This stage allows approval that provides a clear technical reference before the commencement of final fabrication.

Step 4: Manufacturing and In-house Quality Control

Upon approval, the case enters fabrication. Quality control checkpoints are implemented throughout the process, such as inspection of the frameworks, inspection of tooth setup, inspection of the processing accuracy, and last inspection of occlusion and fit before completion.

Step 5: Packaging, Shipping, and Traceability

Cases that have been completed are well-packaged and sent out with appropriate labeling and information. The traceability at this level will make sure that it is possible to trace and review the cases in case of any post-delivery queries.

Step 6: Feedback and Continuous Adjustment

Feedback on the delivery side, whether in regard to fit, esthetics or functionality, is needed after delivery. This cycle of feedback enables the two parties to tune expectations and stabilize quality over time through the process of continued collaboration.

With clearly defined steps and steps to be adhered to, the outsourcing of removable dentures will be a controlled production process as opposed to trial and error exercise.

6. Turnaround Time Expectations for Removable Dentures

The first operational issue that can arise for the laboratories and clinics in case they are considering removable restoration outsourcing is turnaround time. Relative to stereotypes, the production schedule of any given dental laboratory in China is fairly predictable and compliant with international services, as long as the information related to the case is fully disclosed and the workflow is well-defined.

In the case of standard removable restorations, the production time is mostly influenced by manual fabrication processes like tooth setup, processing, and finishing. Chinese laboratories can sustain consistent production cycles by using committed, removable teams and parallel workflows without having to use massive overtime or expedited processing.

General turnaround times are:

- Full dentures: it takes about 5-7 working days to manufacture

- Acrylic partial dentures: 6-8 working days, based on the complexity of the design

- Metal framework partial dentures: typically 7-9 working days, including working on the framework

- Implant-supported overdentures: this type might need more time, depending on attachment methods and verification procedures

The overall time taken in most removable cases would be 7-10 business days when international shipping is added. This range covers production as well as logistics in a normal operation environment.

Although expedited service can be offered on a case-by-case basis, over compression of the timelines can risk remakes. Practically, realistic scheduling, prior planning, and batching of cases are more efficient in terms of ensuring a consistent quality than depending on the urgency of production requests.

7. Pricing Guide for Outsourced Removable Restorations

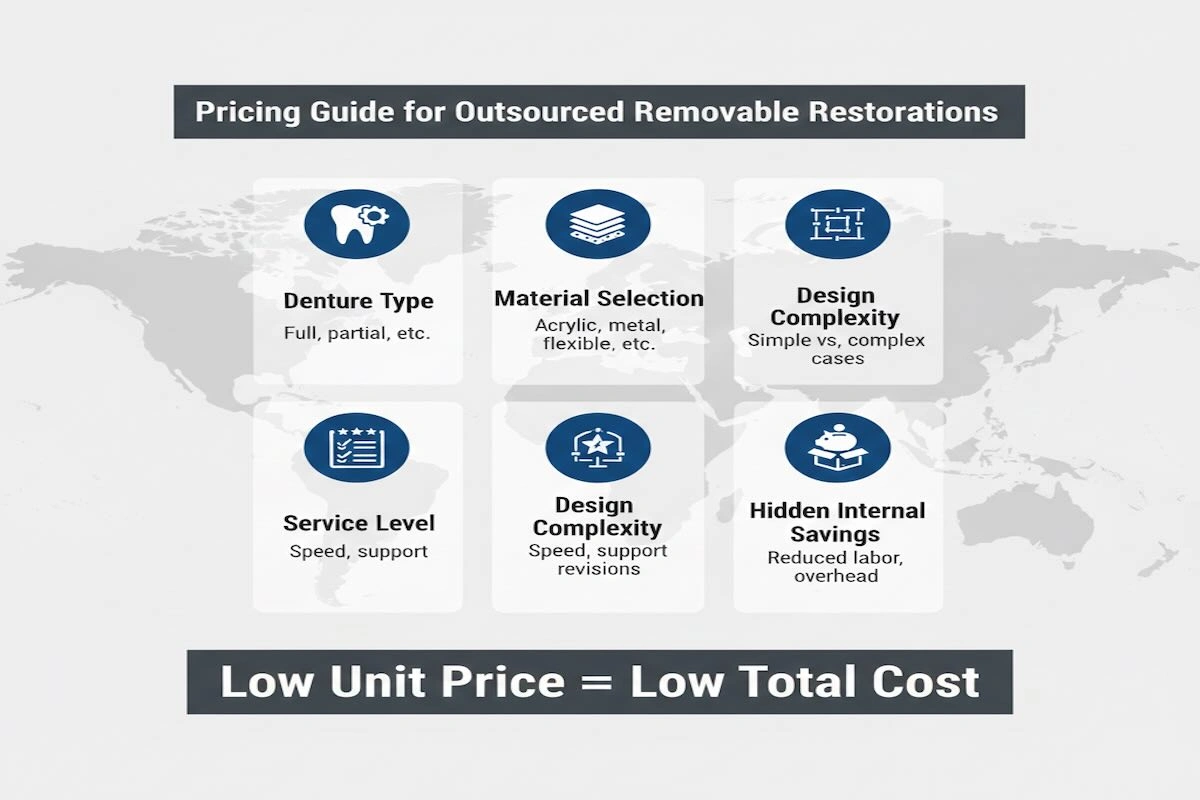

In assessing the cost of outsourcing removable restorations, the laboratories should look at the overall cost and not the unit price. The real efficiency consists of the combination of competitive base pricing and foreseeable quality, fewer remakes, and less internal labor overhead.

Key Factors Influencing Outsourcing Costs:

- Denture type: Complete denture, partial denture, metal frameworks, and implant over dentures will vary in the intensity of labor and material needs.

- Material selection: Standard acrylic foundation, high-grade thermoplastics, or high-quality framework alloys affect the cost of the base as well as its longevity.

- Design complexity: Cases that involve complex occlusion, esthetic customization, or special attachments are cases that demand more technician time.

- Service level: The choice of digital design preview, try-in approvals, or expedited delivery influences the total cost.

- Hidden internal savings: Technician overtime, recruitment, training, and bottlenecks in production are some of the costs that are saved by outsourcing that are not commonly seen in a simple per-unit comparison.

Knowing these aspects, the laboratories can make sound outsourcing decisions that are cost-effective, and yet they do not compromise on the quality and reliability. This is because of its holistic approach that enables one to avoid the pitfall of looking at the lowest quoted price.

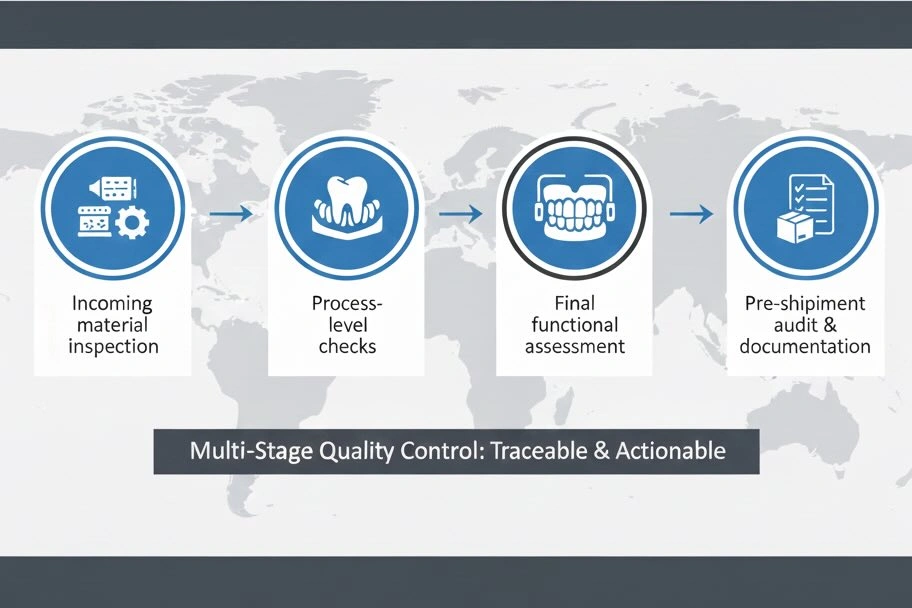

8. Quality Control Systems for Removable Restoration Outsourcing

The basis of successful removable restoration outsourcing is quality control. Effective prostheses are produced in systems that produce consistent fit, functionality, and esthetics that are optimal to meet the clinical needs.

(1) Inbound Material Inspection

In all denture base resins, framework alloys, and teeth, quality, color consistency, and certification are checked before the commencement of the production process. The step is used to avoid the entry of defective materials into the working process.

(2) Process-Level Checks

Technicians check tooth arrangement, occlusion, and framework fit at critical stages during fabrication. Digital devices, try-in models, and intermediate fit tests assist in identifying deviations at an early stage, which minimizes remakes.

(3) Final Functional Assessment

Final dentures are thoroughly assessed in terms of functionality, such as occlusion, articulation, esthetic checks, and customized adjustments to the patient. Any differences are rectified, and then shipping is approved.

(4) Pre-Shipment Audit and Documentation

Photographed, labeled, and logged cases can be traced easily. Packaging is checked to ensure that there is no damage during transportation, and all the documentation is provided to be checked by the clients.

With such multi-phase QC processes, outsourcing partners not only help to minimize the number of errors and remakes but also build confidence and trust in the partner, which creates a framework of long-term cooperation instead of a one-time operation.

9. Communication Requirements to Avoid Remakes

Communication is the key to successful removable restoration outsourcing, where any small misunderstanding may result in remakes or postponements. First, it is necessary to provide the full and detailed information about the case. This involves detailed prescriptions, well-documented bite registration, oral situation photography, and standard forms of case submission. A combination of these factors will give a common reference point between the sending lab and the manufacturing partner.

Then, it is necessary to set up a good communication system that facilitates a response and the resolution of issues in a timely fashion. Response schedules, channels of preference (email, platform messaging, or video calls), and established upgrading directions will enable both parties to rapidly straighten out any confusion before the commencement of production. Indicatively, when a bite record seems to be erroneous, clarification will ensure that remakes are not downstream and that the workflow efficiency is not compromised.

Lastly, uniformity is improved with time through the development of a common language and expectations. In case the same definitions of denture design or material choice or different schemes used in occlusiveness are used by both teams, the chances of being misunderstood are reduced to the minimal. Feedback meetings, review of sample cases, and communication of procedural changes help keep things on track, and case accuracy and corrective work are gradually increased.

With a combination of structured case submissions, formal communication protocols, and continued alignment of terminology, laboratories can drastically reduce the number of remakes, as well as develop an atmosphere of collaboration in outsourcing.

10. Risks and Mitigation Strategies

Several operational risks are associated with outsourcing removable restorations, which may have an impact on the fit, function, and delivery dates. To reduce risks and ensure quality, a clear mitigation strategy should be associated with every risk. The table below highlights the general risks and their preventive measures:

| Risk Category | Cause / Trigger | Mitigation Strategy |

| Design Misinterpretation | Ambiguous prescriptions, unclear bite records, or insufficient photos | Pilot cases, structured case forms, detailed visual references |

| Fit Discrepancies | Inaccurate impressions, improper occlusion recording | QC checkpoints at intermediate stages, try-in verification |

| Shipping & Logistics Delays | Customs clearance, carrier handling, poor packaging | Advanced planning, reliable logistics partners, protective packaging |

| Regulatory / Material Issues | Non-compliant materials or missing documentation | Pre-shipment compliance checks, certified materials, documented approvals |

| Communication Gaps | Misaligned terminology, delayed feedback | Defined communication protocols, response timelines, escalation paths |

Through strategic handling of every risk and mitigation strategies, the laboratories will be able to have a predictable and high-quality process of outsourcing removable restorations. This will help minimize remakes, guarantee on-time delivery, and build on long-term cooperation.

11. How to Choose the Right Outsourcing Partner?

To choose an appropriate removable restoration outsourcing partner, it is not just about price. Critical evaluation guarantees consistent quality, flawless work processes, and extended cooperation. Some of the critical criteria to take into account are:

- Technical Specialization: The partner must possess specialized teams who are well-trained in all dentures, partial dentures, flexible dentures, and implant-supported overdentures. Professional competence decreases repetition and the uniformity of quality.

- Quality Control Systems: The quality control processes should be strong and multi-level, such as inspection of incoming materials, in-process checks, and final functional tests to ensure good results.

- Communication Capability: There is no confusion with unclear protocols, timelines in responding, and common terms are used to reduce the chances of miscommunication and the occurrence of mistakes.

- Scalability and Capacity: The partner must have the capability to process the varying volumes without having to affect the quality or the turnaround times.

- Compliance and Documentation: Knowledge of the international laws, certified documents, and records that can be traced guarantees successful cross-border operations.

- Long-Term Partnership Mindset: An active partner that embraces the sustainability of the partnership, feedback, and continuous improvement will create a stable situation and allow both parties to grow.

To choose just one example, Bestodental focuses on showing itself as a committed collaborator to foreign laboratories, providing organized workflows, skilled denture teams, and clear-cut collaboration frameworks. Through the analysis of possible suppliers against these criteria, laboratories will be able to choose a partner that will not only cater to the short-term production process but also contribute to success in outsourcing in the long run.

12. Who Should Outsource—and Who Should Not?

Whether to outsource removable restorations or not depends on the objectives of operations, the capacity of production, and strategic priorities. Considering the kind of laboratories that would be best served by outsourcing would make decision-making informed because you can decide what to outsource and what not to outsource to ensure that quality, cost, and efficiency are balanced.

1) Labs That Should Outsource

- Dealing with Labor Shortages: Labs experiencing a shortage of technicians can use outsourced teams to keep the production going without overworking full-time employees.

- Cost Pressure: Recruitment, overtime, and training costs and and training costs are minimized through outsourcing, which offers a more predictable cost base.

- Dealing with Volume Fluctuations: Labs with either seasonal or non-periodic demand can expand production effectively without investing in fixed facilities.

- Searching Process Standardization: Outsourcing Partners with structured workflows assist the labs in adopting repeatable and quality-managed processes.

- Seeking International Knowledge: Labs that want to operate with sophisticated digital processes or those that need to meet international quality levels have partners who are skilled in the international markets.

2) Labs That Should Not Outsource

- Same-Day Delivery in Requirement: When time is a factor, as in the case of immediate dentures, it is hard to deal with by remote means because of delays in shipping and coordination.

- Extremely Customized or Complicated Cases: Large bite reconstructions or esthetic corrections that require regular feedback in the chair are more effectively handled internally.

- Operations Labs that cannot be managed remotely, QC checked, or documented in a standardized way might have difficulties with outsourced operations.

Through these requirements, laboratories will be able to identify whether outsourcing is in line with their operations, so that the decision made will contribute to efficiency and clinical outcomes.

13. Outsourcing Removable Restorations FAQs

Many laboratories still have practical questions to make before the final outsourcing decision after getting the workflow, turnaround time, pricing structure, and quality control systems. The following frequently asked questions aim to answer the most widespread operational issues that are not comprehensively discussed in the sections above.

Q1: What is the lowest amount of information needed to prevent remakes?

It should be precise impressions or scans, consistent bite recordings, tooth color, and explicit design guidelines. In the case of partial dentures, the expectations of the framework design should be definite. The most frequent reason for remakes in outsourced removable restorations is the absence or unclear case data.

Q2: What happens to remakes in removable denture outsourcing?

Root-cause analysis is a common method of determining responsibility. Manufacturing-related mistakes are usually re-made free of charge, and those that occurred due to incorrect clinical data might cost more. Before cooperation, there should be clear remake policies that are agreed upon.

Q3: Are outsourced removable dentures able to satisfy the local clinical and esthetic requirements?

Yes, as long as preferences, i.e., occlusal schemes, tooth setup styles, and finishing standards are specified in advance. The Chinese labs are experienced and can adapt, but the unrecorded assumptions used in the process tend to provide inconsistent results.

Q4: Does removable denture outsourcing fit small or low-volume laboratories?

It may be, yet pilot cases and not full transfer should be used by small-volume laboratories. This enables the two parties to level the expectations and stabilize the quality before scaling. When the case flow becomes consistent, then outsourcing is more efficient.

Q5: What is the average time of stabilization in the quality of outsourcing once it has been started?

A majority of the laboratories stabilize after the first 20-30 cases of adjustment. Feedback in this stage is very important to help in the alignment of tooth setup, occlusion, and finishing expectations.

14. Conclusion

Outsourcing removable restorations to China may be a good choice for laboratories and clinics that require scalability, stable quality, and efficiency. Outsourcing can be a strong long-term benefit with the help of a good partner, organized work processes, and controlled quality.

Through efficient processes and teams, labs can minimize remakes, maximize turnaround time, and keep clinical standards high. To make the transition as smooth and controlled as possible, it is recommended to work with an established laboratory like Bestodental and guarantee the predictability of the outcomes and professional help throughout the process.