A common practice of dental clinics and laboratories that are interested in cutting down the operational costs, expanding the production capacity and using a broader spectrum of the available restorative technologies is the fixed restorations outsourcing. In the last ten years, China has become the biggest outsourcer of dental restorations in the world and has been providing millions of zirconia crowns, E.max veneers, implant prosthetics, and full arch systems to dental professionals in North America, Europe, Australia, and the Middle East.

The document outlines all the details that clinics and laboratories should be aware of prior to outsourcing fixed restorations to China. It encompasses the type of products that can be outsourced, expectations of the workflow, shipping and turnaround time, cost, and communication needs, quality management, risks, and the way of choosing an efficient partner. It is aimed to ensure that dental professionals are aware of the outsourcing process in its entirety to be able to make informed choices and provide quality at all times to their patients.

1. What Are Fixed Restorations?

Fixed restorations are fixed prosthetic restorations permanently cemented or screw retained on natural teeth or dental implants. They replace functionality, appearance and longevity of the mouth.

Common fixed restorations include:

- Full contour zirconia crowns

- Multi-layer zirconia restorations

- E.max crowns and veneers

- PFM crowns and bridges

- Inlays and onlays

- Customized implant abutments

- Screw retained crowns and hybrid implant restorations

- Full arch zirconia bridges

Such restorations entail special computer design, milling, ceramic gilding and fine finishing. Most of these procedures are well outsourced to other large scale, digitally equipped Chinese dental laboratories because most of these steps are standardized procedures.

2. Why Fixed Restorations are Suitable for Outsourcing?

Outsourcing can be applied effectively to fixed restorations in particular since they make use of standardized digital and manufacturing processes as compared to subjective and chairside-based methods. The current intraoral scanners generate universal STL files that can be immediately transferred to foreign labs without being distorted and the technicians can start their designing.

The CAD software standardizes critical procedures like margin marking, occlusal morphology, connector thickness, and implant emergence profile, and this significantly minimizes the difference in technicians. Post design, zirconia, PMMA and ceramic restorations are created through automated milling and sintering systems that are guided by worldwide parameters, which assure repeatability and predictability.

Shade communication is also simplified through universal systems like Vita shade guides and multi-layer zirconia materials. Due to the digital, structured, and highly reproducible nature of the whole process, fixed restorations can be produced in large volumes with consistent accuracy. This renders them the best to outsource to the established Chinese dental laboratories, which run large volumes of digital work with consistent quality and dramatically reduced production costs.

3. Why Outsource Fixed Restorations to China?

The following are the benefits of outsourcing fixed restorations to Chinese dental laboratories.

1) Cost Advantages

China has some of the lowest prices in the international dental business, which enables clinics and laboratories to cut the cost of production by 40 percent to 70 percent as opposed to the domestic suppliers.

Large-scale Chinese labs operate high-capacity production lines, centralized milling centers, and streamlined workflows that significantly reduce fixed overhead.

Meanwhile, they take high quality of zirconia and ceramic systems of reputable brands like Aidite, Upcera, and Ivoclar compatible materials. These efficiencies allow the clinics to add more services in their portfolio, reduce the charge to the patient, increase profit margins, and manage more restorative cases without the need to add laboratory costs.

2) Capacity and Scalability

The large production capacity that can be attained in China and not in small or midsize domestic labs is one of the best benefits of outsourcing to China.

The Chinese laboratories usually have a dedicated section in milling of zirconia, ceramic layering, implant prosthetics, PMMA temporaries, and high-end aesthetic work. Through these dedicated teams, labs can manage peak season workloads, provide large multi-unit and full arch cases, and sustain long-run growth of volumes without reducing consistency or turnaround times.

This scalability ensures stable performance even during high-demand periods.

3) Full Digital Workflow Integration

Chinese labs are fully integrated with major global digital platforms, working seamlessly with iTero, 3Shape Communicate, Medit, Carestream, and Primescan, exporting STL files.

Digital case submission eliminates the delays associated with physical impressions and allows laboratories to begin design and production within hours.

This compatibility enables smooth collaboration for clinics and labs worldwide and supports a predictable digital workflow from scan to delivery.

4) Material Availability and Technology Capability

China’s dental manufacturing industry has access to a wide range of advanced materials and production technologies. Most large labs operate both 4-axis and 5-axis milling systems, use high translucency and multi-layer zirconia, and produce E.max restorations through both press and CAD workflows.

Additional capabilities include digital implant abutment design, metal laser melting, traditional casting, and fully digital staining and glazing systems.

With such comprehensive technology under one roof, Chinese labs can manage simple crown cases, multi-unit bridges, and complex implant frameworks with equal efficiency.

5) Global Experience and Support

Chinese dental laboratories serve thousands of international clinics and laboratories, giving them extensive experience in cross-border communication, case management, and product standardization.

Most laboratories offer language support services, documentation, well-formatted communication processes, and well-defined remake policies to facilitate credible results. The many years of working with foreign partners have streamlined their processes, enabling them to produce consistent quality and reliable service on a long-term sustainability basis.

4. What Fixed Restorations Can Be Outsourced?

China can produce virtually every type of fixed prosthetic restoration.

(1) Zirconia Restorations

- Full contour zirconia

- Highly translucent anterior zirconia

- Multi-layer gradient zirconia

- Zirconia bridges and frameworks

Zirconia is the most commonly outsourced restoration due to its predictable milling workflow and high strength.

(2) Glass Ceramics

Chinese labs offer both pressed and CAD versions of lithium disilicate. Common applications include:

- E.max crowns

- E.max veneers

- Inlays and onlays

- Anterior aesthetic cases

(3) PFM Restorations

Porcelain fused to metal remains popular for posterior restorations and bridges requiring strength at lower costs.

(4) Implant-Supported Restorations

Outsourcing implant restorations to China is widely practiced. Available products include:

- Customized abutments for major implant platforms

- Titanium bases

- Screw-retained crowns

- Hybrid abutment crowns

- Full arch zirconia implant bridges

(5) Temporaries and PMMA

- PMMA crowns

- Long term temporaries

- Full arch PMMA try ins

- Diagnostic wax ups

5. How Outsourcing to China Works? Step-by-Step Workflow

The knowledge of outsourcing workflow is the key to a predictable, repeatable, and high-quality result of restorative outcomes. Despite the fact that every laboratory has its in-house procedures, the majority of the established Chinese dental laboratories adopt a comparable digital manufacturing process. The whole process would reduce the gap in communication, accuracy, and efficiency throughout the process of submitting the case to the delivery of the restoration.

1) Step 1: Case Data Collection

The accuracy of the final restoration begins with the quality of the clinical data. Before submitting a case, clinics should gather:

- Intraoral or model scans with clear margins

- Bite registration or buccal bite scans

- Retracted photos that show tooth position, shade, and soft tissues

- Shade and stump shade information, especially for anterior or translucent restorations

- Implant details for implant cases, including brand, platform size, and screw type

Well-prepared data reduces the likelihood of remakes, speeds up turnaround time, and ensures that the laboratory interprets the case correctly on the first attempt.

2) Step 2: Digital Case Submission

Once the data is ready, clinics can send the case digitally using platforms such as:

- iTero (via laboratory ID)

- 3Shape Communicate

- Medit Link

- Carestream CS Connect

- Email submission with STL, PLY, or OBJ files

- Secure file transfer links such as Dropbox, Google Drive, or WeTransfer

Digital submission removes the need for physical impressions and avoids distortions, breakage, or shipping delays. Chinese labs can begin the case immediately upon receiving the files, often within minutes.

3) Step 3: CAD Design and Technical Communication

After receiving the digital data, the laboratory’s CAD team evaluates the scans and begins the design process. This includes:

- Margin marking and verification

- Analyzing occlusal clearance and interproximal space

- Designing anatomy based on functional and aesthetic requirements

- Setting contact points and contour details

- Planning connector thickness for bridges

- For implant cases, designing emergence profiles, abutment shapes, and screw access angulation

Clinics may request a design preview for approval, especially for anterior aesthetics, complex implant restorations, or full arch cases. Real time communication through screenshots, design notes, or short video explanations helps ensure both sides align before manufacturing begins.

4) Step 4: Manufacturing and Material Processing

Once the design is approved, production begins. Chinese labs use advanced digital manufacturing systems to ensure accuracy and efficiency.

(1) Milling

- Zirconia, PMMA, and wax restorations are milled using 4 axis or 5 axis milling units.

- Automated milling ensures precise fit, accurate occlusion, and consistent internal adaptation.

(2) Sintering

- Zirconia units are placed into high temperature sintering ovens.

- Sintering schedules follow standardized temperature cycles to achieve optimal strength and translucency.

(3) Ceramic Pressing and Layering

- E.max restorations may be milled or pressed depending on case type.

- Layered zirconia receives porcelain application for customized texture, translucency, and aesthetic detail.

(4) Implant Assembly

- Custom abutments are milled or designed digitally and bonded to titanium bases if applicable.

- Screw retained restorations are verified for proper channel angulation.

Every step follows predefined digital parameters, ensuring uniformity and predictability regardless of case complexity.

5) Step 5: Quality Control and Case Verification

Chinese laboratories apply multi stage quality control to guarantee accuracy before the case is shipped.

(1) Fit Evaluation

- Internal fit is checked digitally or on printed or milled models.

- Margins are inspected under magnification to ensure precision.

(2) Occlusion and Contacts

- Occlusal points and guidance pathways are verified.

- Proximal contacts are adjusted for proper seating.

(3) Aesthetics and Shade Matching

- Shade accuracy is compared against photos and shade guides.

- Surface texture, contour, translucency, and incisal characterizations are refined.

(4) Implant Restoration Checks

- Screw access orientation is validated.

- Torque tests and fit on digital or analog models are performed.

- A final inspection ensures the restoration meets both clinical requirements and the client’s expectations.

6) Step 6: Packaging, Logistics, and International Shipping

When the QC is finished, the restorations are put into foam inserts, hard protective boxes and moisture-resistant material to package them securely. The Chinese laboratories normally use world express companies like DHL, UPS and FedEx to ship.

Typical delivery times include:

- North America: 3 to 5 days

- Europe: 4 to 6 days

- Australia and New Zealand: 3 to 5 days

- Middle East: 4 to 7 days

Many labs offer weekly consolidation services to reduce freight costs for clients with regular case volumes. Tracking numbers are provided immediately after dispatch, ensuring full visibility during transit.

6. Expected Turnaround Times of Fixed Restorations Outsourcing

The table presented below is a summarized version of the approximate turnaround time that the outsourcing of fixed restorations to China is expected to experience. It contains the averages of the production time of various types of restorations, the approximate international shipping timeframes, and the main aspects that could affect the general timeframes. The summary can assist clinics and laboratories in better planning their cases, making more achievable expectations, and scheduling patient appointments with more certainty.

| Category | Item | Time / Description |

| Production Time | Full contour zirconia | 3 to 4 days |

| Layered zirconia | 5 to 6 days | |

| E.max | 4 to 5 days | |

| Customized abutment | 4 to 6 days | |

| Implant crown | 5 to 7 days | |

| Full arch zirconia | 8 to 12 days | |

| Shipping Time | North America | 3 to 5 days |

| Europe | 4 to 6 days | |

| Australia | 3 to 5 days | |

| Middle East | 4 to 7 days | |

| Factors Affecting Turnaround | Case complexity | Multi unit, implant, and full arch cases require longer time |

| Incomplete data | Missing shade, unclear margins, incorrect bite records delay production | |

| High volume seasons | Peak periods may extend production queues | |

| Implant components availability | Special or uncommon platforms may require sourcing time |

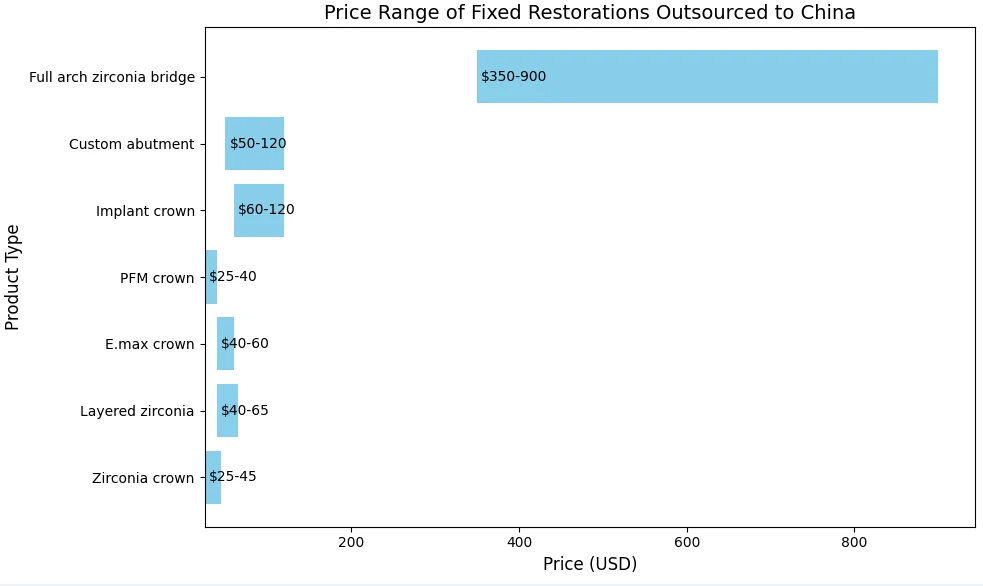

7. Fixed Restorations Outsourcing Pricing Guide

The following will discuss the pricing of outsourced fixed restorations from three perspectives: pricing range references, factors influencing pricing, and a comparison between pricing in China and local pricing.

1) Pricing Reference Table

Preferred pricings of the popular fixed restorations that are outsourced to China are listed in the table below. The prices will be actual and can also fluctuate depending on the material brand, aesthetic needs, and the complexity of the case, but these reference ranges can be used to establish a clear base of cost savings and budgeting of treatment.

| Product Type | Typical Price Range (USD) |

| Zirconia crown | 25 to 45 |

| Layered zirconia | 40 to 65 |

| E.max crown | 40 to 60 |

| PFM crown | 25 to 40 |

| Implant crown | 60 to 120 |

| Custom abutment | 50 to 120 |

| Full arch zirconia bridge | 350 to 900 |

2) Factors That Influence Pricing

The cost of fixed restorations outsourced is influenced by a number of variables. Having these factors enables the clinics and laboratories to assess the quotes more precisely and budget the treatment more efficiently.

(1) Material Brand

The choice of material is one of the biggest price determinants. High translucency zirconia, premium multilayer blocks, and branded lithium disilicate such as E.max typically cost more than standard options. Established brands offer improved aesthetics, strength, and color stability, which increases material expenses and technician handling time.

(2) Anterior vs Posterior Location

Layering or characterization may be necessary, and anterior restorations need to be more aesthetic and morphologically tailored. The posterior restorations tend to be more functional than aesthetic in nature, therefore they are usually less expensive. The level of artistic work needed for front teeth directly influences the final cost.

(3) Aesthetic Requirements

Cases requiring special staining effects, internal characterization, layered porcelain, detailed surface texture, or customized anatomy demand more technician time and skill. This additional labor increases pricing, especially for cosmetic veneers, high visibility crowns, and complex smile design cases.

(4) Implant Platform Type

Implant restoration pricing varies significantly depending on the implant system used. Common platforms like Straumann, Nobel, and MIS are readily available and therefore cost less. Less common or discontinued platforms may require specific components or third party parts, which can add sourcing time and additional costs. Angulated screw channel restorations also require more advanced CAD design.

(5) Number of Units

Multi unit cases usually benefit from economies of scale. The unit cost may be lower when two or more crowns, bridges or full arch restorations are ordered together due to the ability of design, setup and production steps to be shared amongst units. Single unit orders typically carry higher per unit fees.

3) China Versus Local Pricing

Chinese dental laboratories typically offer fixed restorations at one third to one half of the cost charged by local laboratories in North America, Europe, and Australia. This notable price disparity is informed by a number of structural capabilities such as increased capacity of production, centralized digital processes, reduced operating expenses and availability of competitively priced yet competitive quality materials. Regardless of the cheaper prices, the quality of restorations made in China is comparable and in most aspects higher than that of smaller local labs because of high level milling machines and common quality control.

In the case of clinics and laboratories, such savings are directly reflected in the performance of the business. This will result in lower production costs, which in turn will enable providers to live on a healthier margin, less pressure, and provide more competitive prices to patients without having to cut corners or sacrifice on material choice or aesthetic results. Outsourcing will also allow the clinics to invest their savings into new equipment, digital upgrades or additional services. Due to this, outsourcing to China is not merely a cost reduction measure but a long term operational benefit that can be used to scale and be efficient.

8. How Chinese Dental Labs Realized Fixed Restorations Quality Control?

One of the most significant things about outsourcing fixed restorations is the maintenance of predictable and consistent quality. The Chinese dental laboratories are well established with heavy investment in digital facilities, standard work procedures, and training of the technicians to make sure that all the restorations satisfy the international requirements. Their quality control systems are designed such that they are multi-layered, structured and are highly transparent such that clinics and laboratories trust that they can outsource without any adverse effects on patient outcomes.

1) Standard QC Procedures

Reliable Chinese labs follow a structured multi step QC workflow that covers both digital design and physical fabrication.

(1) Initial File Review

On reception of the case, technicians ensure that the scan is clear, margin is visible, and the relationships of the occlusives and the accuracy of the bite are correct and that the implant details are clear. Whenever there are any problems like unclear margins, lack of sufficient reduction, or improperly set bite position then it is signaled right away to prevent errors downstream.

(2) Margin and Design Verification

In the CAD stage, the senior technicians check marking of margins, path of insertion, connector size to use in bridges, morphology of the occlusals, and contact points. This makes sure that the digital design is technically correct prior to the production process.

(3) Milling Thickness and Structural Check

Once the system is designed, minimum thickness of zirconia, PMMA or ceramic restorations is automatically assessed. This eliminates fractures or weak areas during milling, sintering, or other clinical use in the long term.

(4) Fit and Contact Adjustments

Once milled or pressed, restorations undergo internal fit verification on digital models, resin models, or printed dies. Proximal contacts, occlusal contacts, and seating accuracy are fine tuned to minimize chairside adjustment time.

(5) Final Aesthetic Inspection

Before packaging, restorations are inspected for shade accuracy, surface texture, contour symmetry, translucency, and staining quality. For implant restorations, the screw access position and emergence profile are also checked.

This layered QC approach ensures that restorations remain consistent across technicians, departments, and production cycles.

2) Branded Materials

Material quality plays a major role in the long term success of fixed restorations. Many Chinese labs use internationally recognized zirconia and ceramic systems such as:

- Aidite

- Upcera

- Ivoclar compatible zirconia

- Kuraray

- Vita porcelain powders and shade systems

These brand names offer consistent strength, consistent color grading, and durability. With proper compliance to the milling and sintering standards by the manufacturers, Chinese laboratories can attain the same or even better results as most local labs do.

The branded materials would also make it traceable and guarantee the clinics have restorations that are of world standards and not low grade ones.

3) Digital Traceability

Modern Chinese dental labs implement digital tracking systems that record every step of the production process, including:

- Material batch and LOT numbers

- Design files and version history

- Technician assignments

- Milling and sintering logs

- Quality control notes

This digital traceability ensures consistency across different cases and enables quick review if adjustments or remakes are needed. It also provides transparency that many clinics value when outsourcing internationally.

4) Final Documentation

To support clear communication and establish confidence, many Chinese labs provide comprehensive final documentation with each case. These may include:

- Case Photos: High resolution images showing the final crown, contacts, occlusion, and shade.

- Shade Confirmation: Documentation comparing the restoration with the requested shade and stump shade information.

- Implant Interface Details: For implant restorations, labs provide platform information, component compatibility notes, and screw access angulation confirmation.

- Rework or Adjustment Notes: If modifications were required during production, technicians include comments so clinics understand what has been adjusted and why.

This transparency improves case communication, reduces chairside adjustment time, and strengthens long term collaboration between clinics and outsourcing partners.

9. Communication Requirements to Avoid Remakes

If there is poor communication with the dental laboratory, it is highly likely that remakes will be necessary. So how can this be minimized? Here are some suggestions.

(1) Most Common Causes of Remakes

- Insufficient occlusal reduction

- Unclear margins

- Incorrect bite registration

- Missing photos or shade data

- Incomplete implant details

(2) What Clinics Must Provide

For best results, supply:

- Retracted shade photos

- Stump shade for veneers and anterior crowns

- Clear margins with clean scans

- Verified bite scans

(3) Best Practices

- Use consistent scan protocols

- Confirm occlusal clearance clinically

- Include all photos for aesthetic cases

- Communicate special requests clearly

10. Risks of Fixed Restorations Outsourcing and How to Mitigate Them?

The following are some tips about how to mitigate risks of outsourcing fixed restorations.

(1) Shipping Delays

Mitigation:

- Plan shipping buffers

- Use express couriers

- Request consolidated shipments

(2) Material Transparency

Mitigation:

- Request LOT numbers

- Confirm brands used

- Ask for material consistency

(3) Aesthetic Miscommunication

Mitigation:

- Provide shade and face photos

- Provide stump shade

- Approve CAD designs for anterior cases

(4) Complex Implant Cases

Mitigation:

- Provide complete implant data

- Share radiographs if needed

- Confirm screw access angulation

(5) Ensuring Consistency Across Cases

Mitigation:

- Work long term with a single team

- Use standard protocols

- Request technician notes

11. How to Choose a Reliable Chinese Fixed Restorations Outsourcing Partner?

The selection of an appropriate outsourcing partner is among the most crucial choices that clinics and dental laboratories trying to get the regular, high-quality fixed restorations can make. Since fixed prosthetics are based on computer procedures, computerized milling, and correct aesthetic perception, the ability and stability of your partner are tangible clinical outcomes and patient satisfaction. The next set of criteria will be useful in assessing the Chinese dental labs before developing long term cooperation.

a. What to Look For

What should we pay attention to when choosing a reliable Chinese outsourcing partner for fixed dental restorations?

(1) Proven Experience With International Fixed Restorations

A strong outsourcing partner should have years of experience working with overseas clients and handling zirconia, E.max, implant crowns, bridges, and full arch restorations. Ask for clinical photos, design examples, and long term client references.

(2) Digital Compatibility With Your Existing Workflow

Your scanner, and other formats as iTero, 3Shape, Medit, Carestream, Primescan, STL, OBJ or PLY are all scanners that the lab should support. Digital only compatibility ensures easy submission, reduced mistakes and quick turnaround.

(3) Specialized Departments for Fixed Restorations

Reliable Chinese labs typically have designated teams for:

- Zirconia design and milling

- Ceramic layering and anterior aesthetics

- Implant restorations and custom abutments

- Bridge and full arch zirconia frameworks

This specialization ensures each case is handled by technicians with the right expertise.

(4) Strong Understanding of Occlusion and Margin Integrity

Fixed restorations rely greatly on the proper marking of the margins, scheme of occlusion, and the thickness of a connector to bridge. The outsourcing partner must show:

- Accurate margin isolation

- Proper occlusal mapping

- Knowledge of minimum thickness standards

- Understanding of functional occlusion

These core competencies reduce remakes and chairside adjustments.

(5) Clear, Fast, and Technical Communication

Your account manager should respond promptly, address technical questions professionally, and provide design previews for complex cases. Smooth communication is essential for predictable outsourcing.

(6) Structured Multi-Step QC Workflow

Look for documented QC processes that include:

- File analysis

- Margin and design verification

- Milling and sintering checks

- Fit and contact validation

- Final shade and aesthetic inspection

A lab without QC documentation cannot guarantee consistency.

(7) Stable Production Capacity

Because fixed restorations often require tight scheduling, choose a lab with:

- Sufficient technicians

- Multiple milling machines

- Implant and ceramic departments

- Ability to handle seasonal volume spikes

- Consistency in delivery is as important as quality.

(8) Transparent Policies

A reliable outsourcing partner provides clear policies on:

- Turnaround time

- Remakes

- Shipping schedules

- Case approvals

- Additional fees

This protects both the clinic and the laboratory.

b. Before Starting Cooperation FAQs

These practical questions help evaluate a lab’s competency and reliability:

(1) What zirconia and ceramic materials do you use?

Ensure they use branded materials such as Aidite, Upcera, Ivoclar compatible zirconia, and high quality porcelain powders.

(2) What is your average remake rate for fixed restorations?

A remake rate between 3 percent and 7 percent is acceptable. Higher rates may indicate design or QC issues.

(3) Can you provide design approval before milling, especially for anterior or implant cases?

Design previews prevent misinterpretation of esthetics, occlusion, and implant angulation.

(4) Which implant systems do you support, and do you stock common platforms?

A reliable partner should support:

- Straumann

- Nobel

- MIS

- Astra

- Zimmer

- Neodent

Confirm availability of components to avoid delays.

(5) What are your standard and rush turnaround times?

Clear timelines help clinics schedule patient appointments confidently.

(6) Do you have real case photos, before and after examples, or full arch documentation?

Clinical evidence demonstrates actual capability rather than claims.

(7) Do you support both monolithic and layered zirconia work?

If the lab does not layer ceramic, anterior aesthetics may be limited.

c. Red Flags to Avoid

These warning signs often indicate unreliable or inexperienced outsourcing partners.

- Lack of QC Workflow Documentation: If the lab cannot explain its QC stages, consistency will be unpredictable.

- No Real Case Portfolio: Stock photos or generic samples often signal that the lab has minimal real experience.

- Weak or No Implant Expertise: Implant restorations require exact screw channel angulation, emergence profile design, and torque accuracy. A lab without implant capability is not suitable for long term fixed restoration outsourcing.

- Unclear or Adaptable Pricing: When prices are hidden, quoted vaguely or they are not consistent, then this usually signals a problem in operations.

- Slow or Unreliable Communication: Delay in response normally implies delays in design, troubleshooting, and approval of cases.

- Overpromising Capabilities: Statements like “We never have remakes” or “We can produce unlimited volume” are unrealistic and should be approached with caution.

- Frequent Shipping or Production Delays: If problems occur repeatedly during the trial phase, they will worsen with higher case volumes.

An effective Chinese fixed restorations outsourcing partner should be well digitally compatible, have special technical knowledge, documented quality control (QC), transparent communication, and consistent production capacity. The practice of assessing abilities carefully and detecting red flags at an early stage can help a clinic and a laboratory to build stable all-time relationships producing high-quality and predictable outcomes and helping to maintain the growing process.

12. Who Should Outsource and Who Should Not?

The following lists who is suitable for outsourcing fixed restoration work and who is not.

(1) Outsourcing Is Ideal For

- Busy clinics with growing case volumes

- Small or midsize labs needing extra production support

- Clinics wanting access to zirconia or implant technology

- Providers looking to reduce costs without lowering quality

(2) Outsourcing Is Not Ideal For

- Same day chairside restorations

- Cases requiring in person patient try ins

- Ultra aesthetic veneer cases requiring artistic layering

- Immediate emergency cases requiring one day turnaround

13. Outsourcing Fixed Restorations to China FAQs

The following are some common questions about outsourcing fixed restorations.

(1) Is the quality of restorations from Chinese labs comparable to local labs?

Yes. Reputable Chinese labs use the same digital workflows, branded zirconia, ceramic systems, and milling technologies as many Western labs. With proper QC procedures and technician specialization, the quality is consistent and comparable to local production.

(2) How do I send cases to a Chinese lab?

Most labs accept files from iTero, 3Shape, Medit, Carestream, and Primescan. You can submit cases directly through digital platforms or send STL files via email or secure file transfer systems.

(3) What is the typical turnaround time for outsourced fixed restorations?

Production usually takes 3 to 7 days for single unit crowns and 8 to 12 days for full arch zirconia. Shipping via DHL, UPS, or FedEx adds another 3 to 6 days depending on your region.

(4) Are my patient scans and information secure?

Established Chinese labs follow strict confidentiality measures. Digital submissions are encrypted, and files are stored securely. Labs serving overseas markets understand international privacy expectations.

(5) What should I include when submitting a case?

Provide clear scans, a verified bite, retracted photos, shade and stump shade information, and complete implant details when applicable. The more complete the data, the fewer the remakes.

(6) What is the average remake rate for outsourced restorations?

A normal remake rate is around 3 percent to 7 percent. Proper preparation, accurate scanning, and complete case information help reduce remakes significantly.

(7) How do Chinese labs handle implant restorations?

Most experienced labs support major systems such as Straumann, Nobel, MIS, Zimmer, Astra, and Neodent. They can fabricate custom abutments, screw retained crowns, hybrid restorations, and full arch zirconia frameworks.

(8) Do I get to approve the design before production?

Yes. Many labs offer design previews for anterior aesthetics, implant restorations, and complex cases. Approving the design ensures accuracy and reduces communication issues.

(9) Are there hidden fees I should be aware of?

Transparent labs provide clear pricing for materials, implants, layered ceramics, and shipping. Always request a complete price list and ask about rush fees, remake policies, and implant component costs.

(10) What is the best way to start working with a Chinese outsourcing partner?

Begin with a few single unit trial cases to evaluate occlusion accuracy, shade matching, turnaround time, communication, and consistency. Once you are satisfied, you can gradually expand to bridges, implants, and full arch cases.

14. Conclusion

Outsourcing fixed restorations to China has become one of the most efficient ways for dental clinics and laboratories to expand capacity, reduce costs, and improve workflow efficiency. With the growing global adoption of digital impressions, Chinese laboratories now integrate seamlessly with international systems and offer predictable results across zirconia, E.max, PFM, and implant supported restorations.

By understanding the outsourcing workflow, communication requirements, quality control standards, risks, and supplier selection strategies, dental professionals can establish long term partnerships that deliver reliable, aesthetic, and cost effective restorations for their patients. Outsourcing is no longer a backup option. It is now a core component of modern dental production, helping clinics and labs scale smarter and operate with greater efficiency in an increasingly digital world.