Within the last ten years, dental outsourcing has developed beyond a cost-driven solution to a strategic operating model that is embraced by laboratories and clinics all over the world. What was initially taken with some doubt is now a fully grown, formal solution which facilitates scalability, uniformity, and long-term expansion- especially in fixed restorations.

IPS e.max is among the most outsourced products, especially crowns and veneers in esthetic areas of all the ceramic materials. Its power, transparency, and digital suitability give it an exceptionally good fit to cross-border production when it is facilitated by well-organized workflows and quality management.

The guide will be targeted at dental laboratories, multi-location clinics, and decision-makers seeking to gain a clear, practical, and comprehensive idea of how to outsource E.max crowns and veneers in China. As opposed to the marketing claims, the current article deals with the actual operational issues: what can and cannot be outsourced, the way workflows are handled, the way quality is managed, the risks involved, and how to select the appropriate partner. When you are considering outsourcing E.max for the first time or you need to streamline an already existing supplier relationship, this guide will provide you with clarity, predictability, and confidence.

1. What Are E.max Restorations?

E.max is a type of lithium disilicate glass-ceramic system created by Ivoclar that is popular in contemporary restorative dentistry. It is mostly used in crowns, veneers, onlays, and inlays, as well as partial coverage restorations, particularly in the anterior areas and in premolar areas where esthetics are paramount.

To a layman, E.max may be referred to as a ceramic substance that has been designed to closely mimic natural tooth enamel. Its optical characteristics enable it to transmit light and reflect similarly to natural teeth, creating depth, translucency, and lifelike transitions of color instead of a flat or opaque look.

Mechanically, E.max provides a flexural strength of 360-400 Mpa which is much greater than conventional feldspathic ceramics. This property allows thinner restorations and less invasive preparations without compromising the consistent clinical performance in case of appropriate bonding.

Two major methods are used to make E.max restorations:

- Press Technique in which the patterns are pressed on using ceramic ingots.

- CAD/CAM Milling, in which restorations are pre-crystallized blocks digitally designed and milled.

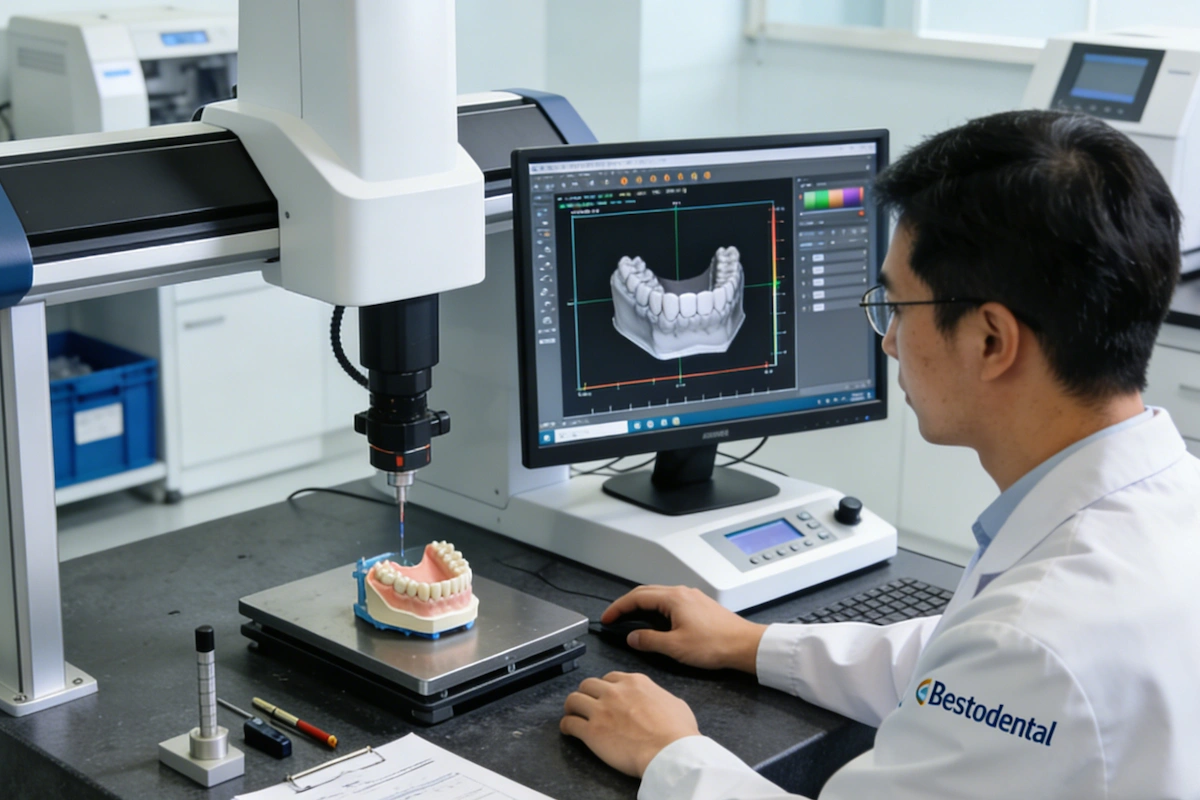

CAD/CAM-milled E.max restorations prevail in the outsourcing environment. Digital processes provide consistency, repeatability, and scalability- the major demands of offshore production. Following the milling, restoration is carried out to crystallization, staining, layering (where necessary), and glazing to the required aesthetic effect.

E.max is neither a niche nor an experimental product. It is a material that is globally accepted, clinically proven, and seamlessly fits in digital dentistry and, as a consequence, is a logical outsourcing candidate.

2. Why Is E.max Suitable for Outsourcing?

Not all types of dental restorations can be outsourced. E.max crowns and veneers, nevertheless, have a number of natural properties that render them outsourcing-friendly.

First, the E.max work processes are highly standardized on a global scale. Design preparations, margin requirements, minimum thickness requirements, bonding procedures, and shade systems are universal across markets. This minimizes the interpretation issues between dentists, local labs, and overseas production teams.

Second, E.max restorations are computer-controlled throughout their manufacturing. The vast majority of cases are based on intraoral scans or digitized impressions, and there is no danger of transferring insufficient data because of the risks and time loss of physical models. Digital design reduces subjectiveness and enhances cross-border reproducibility.

Third, E.max is usually utilized in single-unit or small esthetic cases. In contrast to full-mouth rehabilitations or complicated implant-supported restorations, crowns and veneers adhere to the logic of repeatable designs and predictable esthetic parameters, which are less challenging to control remotely.

Lastly, E.max is the best to outsource to due to its cost-to-value ratio. Although the true E.max materials are priced in a global manner, labour and operational efficiencies contribute significantly towards the overall cost. Outsourcing enables the laboratories and clinics to keep the high esthetic standards and enhance the margins or provide patients with more competitive prices.

3. Why Outsource E.max to China?

China has emerged as the biggest dental outsourcing center in the world, and this status has not been achieved through short term cost benefits but the long term structural growth.

One of these is the size of manufacturing. There is a large pool of trained dental technicians in China, with many being specialists in the field of fixed restorations. Huge labs regularly generate hundreds or thousands of E.max units per day, which allows the laboratory to maintain capacity, reliably output, and have a high turnaround time even with peak demand.

Another significant driving force is cost efficiency. Although the real E.max blocks are supplied all over the world, labour, infrastructure, and cost of operations in China are a lot cheaper compared to North America, Europe, or Australia. This enables the international customers to make significant savings without sacrificing the material authenticity.

Technical maturity is also very significant. Most of the major Chinese dental laboratories have experience of 10-20 years of serving the foreign markets. They are conversant with international standards of preparation, occlusal concepts, shade systems, and expectations of communication. Several labs have esthetic teams that are specifically devoted to anterior E.max crowns and veneers.

Moreover, China is also highly connected with digital dentistry ecosystems. Open STL processes, cloud-based case management software, CAD/CAM software, and multilingual customer services have become the norm among well-established vendors.

In the case of international laboratories and clinics, China is a unique blend of size, experience, affordability, and digital preparedness.

4. What Can and Cannot Be Outsourced?

The scope of outsourcing helps to have realistic expectations and to establish trust between clinics, laboratories, and foreign partners.

1) What Can Be Outsourced Successfully

- E.max (anterior and premolar) single-unit crowns: These are built on standardized principles of preparation and design and fit, occlusion, and esthetics in such cases are very predictable when working offshore.

- Normal and low-prepared E.max veneers: The veneer shape and translucency can be digitally controlled with clear scans, stump shade information, and reference photos.

- Inlays and onlays: CAD/CAM-based inlays and onlays can be manufactured with consistent marginalization and stable occlusal relationships with minimal risk of interpretation.

- Online wax-ups and smile design proposals: Cases of digital planning can be done effectively offshore and give visual instructions without undertaking committed fabrication.

- Esthetic try-in restorations: Try-in units are useful to test shape and proportion before final delivery to minimize uncertainty in esthetic cases.

2) What Is Less Suitable for Outsourcing

- Same-day or chairside restorations: These orders demand immediate manufacturing and delivery, which can not be done in connection with international logistics.

- Highly subjective esthetic cases: Remote production is a higher risk of remakes when the results have a high reliance on in-chair adjustments or patient feedback.

- Patients who need various shade changes: The changes in color at the chairside are hard to control on the borders.

- Poorly prepared teeth with unclear margins: Even the best laboratory skills cannot provide accurate interpretation when there is no clarity in preparation data or inconsistency.

Clinical judgment is not taken away by outsourcing. Cases that need speed, real-time interaction, or subjective adjustment are more suited to local production, whereas clear-cut cases that can be digitally communicated are best suited to offshore production.

5. Step-by-Step Outsourcing Workflow

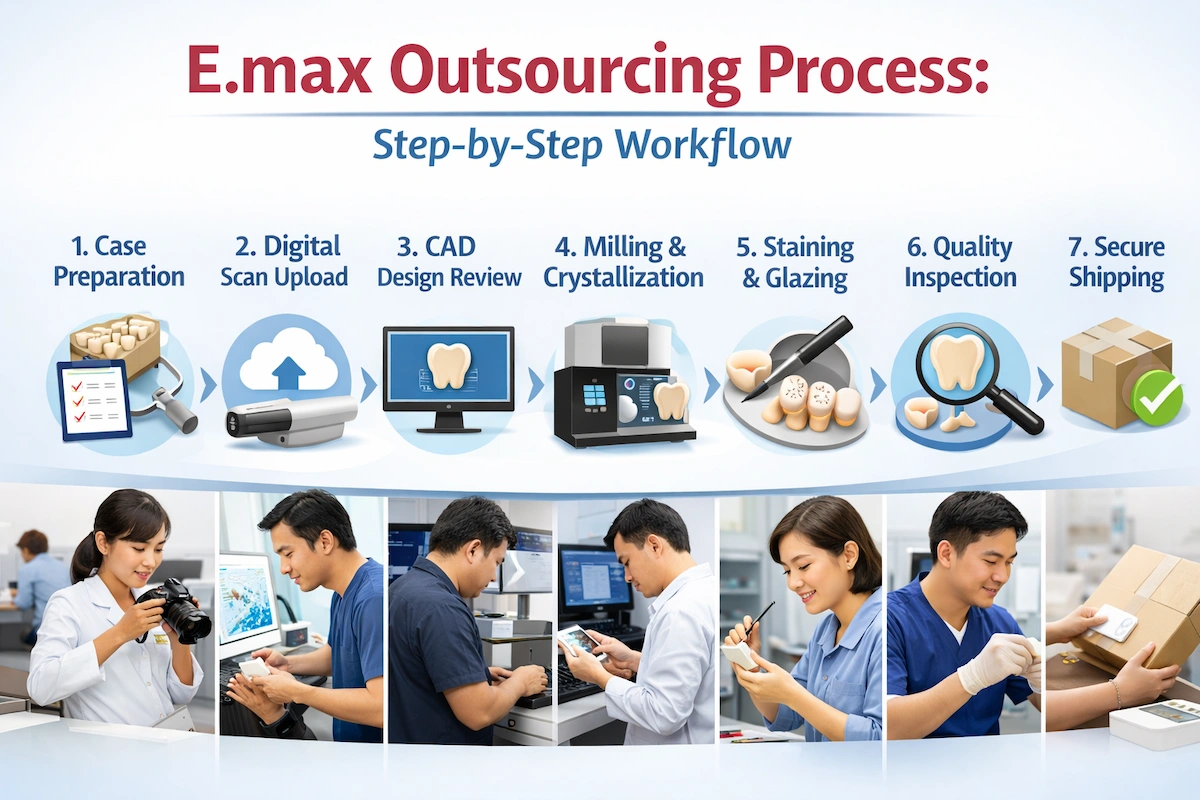

The most important aspect of the production of E.max crowns and veneers in a foreign country is a well-defined workflow of outsourcing so that the same outcomes can be guaranteed. The cross-border outsourcing entails increased dependence on transparency of the processes, data, and predictable handoffs as opposed to local production. On the one hand, when every single step is standardized and controlled, outsourcing turns into a repeatable system as opposed to a risk per case.

The following is a sample workflow of professional Chinese dental laboratories in dealing with E.max crowns and veneers cases of international customers.

Step 1: Case Evaluation and Tooth Preparation

It starts at the chairside, where the dentist will assess the suitability of the case for E.max and to outsource. The preparation of the tooth is done in accordance with the accepted E.max protocols, and specifically, the depth of reduction, gradual transitions, and margins. The clinical underpinning is established at this point–any loss of quality in the preparation will be a direct reflection on the accuracy further down the line, notwithstanding the prowess of the laboratory.

Step 2: Collection of Digital Data and Submission

After some preparation has been done, digital impressions or scanned models are taken and inspected to ascertain the clarity. Besides the primary scan data, supplementary information like intraoral photos, shade choices, stump shade details (particularly in the case of veneers), and prescription notes are gathered. The next thing that is done is to upload all the files under the case management system of the outsourcing partner so that technicians have complete and interpretable data, as opposed to a piece of information.

Step 3: CAD Design and Esthetic Planning

The technicians plan the restoration digitally using the data provided. Functional components like margin fit, contact points, and occlusal relationships are determined at this stage, and esthetic parameters like facial contour, incisal edge position, and emergence profile are optimized. In the case of veneers, thickness distribution and the translucency areas are given great consideration to facilitate a realistic outcome following bonding.

Step 4: Design Review and Pre-Production Confirmation (Optional)

In more esthetically sensitive cases, a preview of the design or digital wax-up can be sent to the client to review. This is an optional checkpoint that enables dentists or even laboratories to check the overall shape, proportions, and esthetic direction before the fabrication is done. Although it is not mandatory in all cases, the step can help avoid a large amount of uncertainty and reduce risk in anterior restorations.

Step 5: Milling, Crystallization, and Characterization

The restoration is milled after design approval using the calibrated CAD/CAM equipment, using genuine E.max blocks. The milled units are then subjected to crystallization so as to have complete material strength and optical properties. Restorations can be stained, overlaid, or internally marked according to the needs of the case, and then finished with glazing, a tradeoff between esthetics and structural integrity.

Step 6: Final Inspection and Quality Control

Finished restorations undergo several quality control measures before being shipped. These are marginal integrity verification, proximal contacts verification, occlusion, shade accuracy, and surface finish verification. The anomalies noted in the QC phase are rectified in-house, such that only restorations that can be accepted by the clinicians proceed to delivery.

Step 7: International Shipping and Packaging

Upon approval, restorations are packaged well and sent using labeled international logistics services to avoid destruction during transmission. Each case is clearly labeled and documented, and it is therefore recognized, checked, and processed by the receiving clinics or laboratories efficiently.

6. Production and Delivery Timeline for E.max Outsourcing

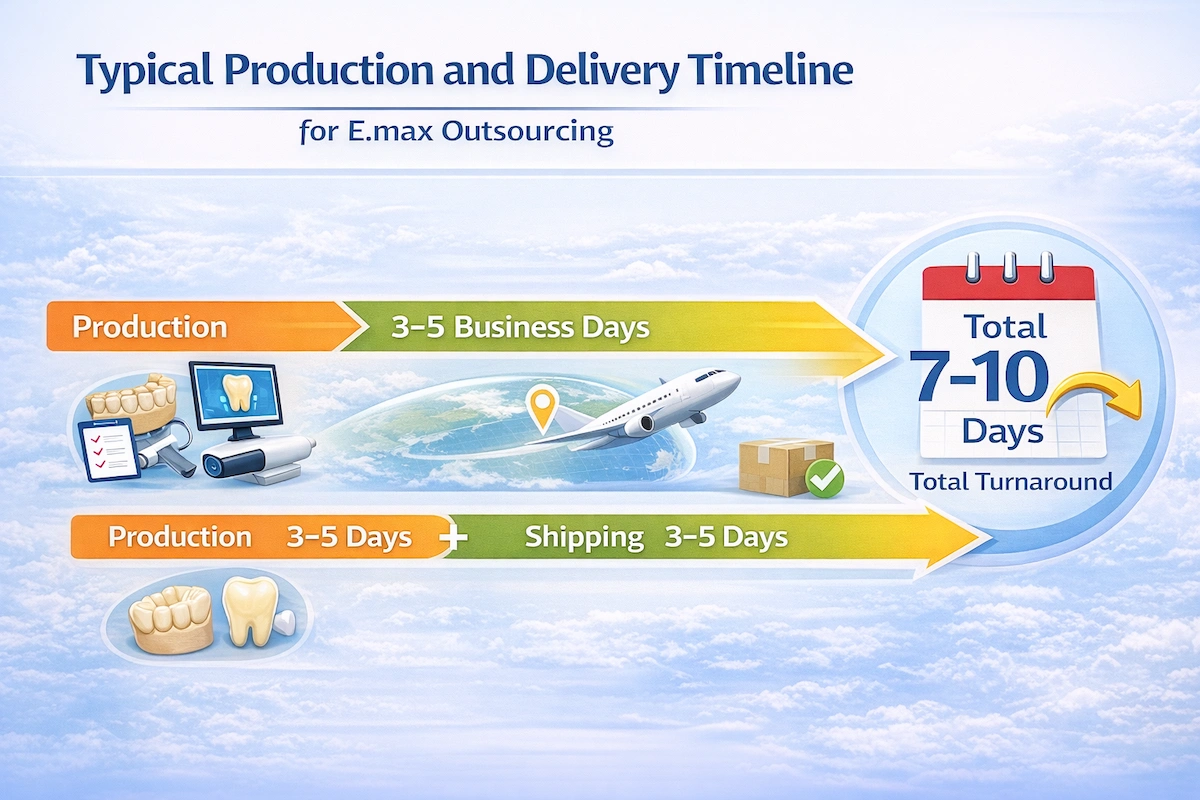

The first operation factor that is usually addressed by the laboratories or clinics in offshore production is the turnaround time. Turnaround can, however, be inferred as misleading when gauged as days required alone. A better way to do it is to get knowledge of how time is allocated between production, quality control, and logistics, and what of it is predictable or variable.

In the case of E.max crowns and veneers outsourced to China, the turnaround time tends to remain constant in the event that there is standardization of the workflows, and the communication is full.

Normal time breakdown in E.max outsourcing is shown below:

(1) Phase of production (3-5 working days)

CAD design, milling, crystallization, staining or layering, glazing, and internal quality inspection are all part of this stage. In cases when case data is clear and no redesign is necessary, single-unit E.max crowns and veneers typically fall within this range.

(2) Quality Control Buffer (0-1 working day)

To take into consideration the minor adjustments found during inspection, professional labs construct a QC buffer. This is a step that is not visible to the clients but which is very important in avoiding downstream remakes.

(3) International Shipping (3-5 calendar days)

The time of shipping is contingent upon the destination country, the effectiveness of the customs clearance, and the level of courier services. The majority of the seasoned outsourcing partners rely on the already existing express logistics routes to ensure uniformity.

(4) Full Expected Turnaround: 7-10 working days

It should be mentioned that fast services may reduce the time of production, but timelines that are forced or attempted to be forced are risky. In the case of esthetic restorations, like E.max veneers, predictability tends to be more beneficial than speed.

7. E.max Outsourcing Cost Structure and Pricing Considerations

The second consideration, which is usually important after the turnaround time is pricing. Nevertheless, to make a meaningful cost analysis, one has to have an idea of the unit price, as well as what services are provided by default, and what factors can make the final price higher. The following table provides a standard pricing system of outsourced E.max crowns and veneers of the Chinese professional dental laboratories.

| Item | E.max Crown | E.max Veneer | Pricing Notes |

| Typical Price Range (USD) | 30–60 | 35–70 | Reference range: varies by volume and aesthetic complexity |

| Material | Genuine E.max | Genuine E.max | Authentic Ivoclar blocks with batch traceability |

| CAD Design | Included | Included | Functional and aesthetic digital design |

| CAM Milling & Crystallization | Included | Included | Standard CAD/CAM production workflow |

| Standard Staining / Glazing | Included | Included | Suitable for most routine esthetic cases |

| Advanced Esthetic Layering | Optional | Often Optional | May increase cost for high-demand anterior cases |

| Quality Control | Included | Included | Multi-level QC before shipment |

| Basic Remake Policy | Included | Included | Coverage depends on responsibility attribution |

| Complex Shade Matching | Possible Add-on | Possible Add-on | Multi-zone translucency or custom brightness |

| Low-Volume / Irregular Orders | May Affect Price | May Affect Price | Higher unit cost without volume consistency |

| Extended Warranty or Remake Terms | Optional | Optional | Negotiated in long-term partnerships |

How to Interpret Pricing Correctly:

Instead of concentrating on the lowest unit price, the experienced laboratories and clinics consider pricing as the total cost of operation. Issues like remake rate, chairside adjustment time, communication efficiency, and long-term consistency are likely to have a larger financial effect than minor variations in per-unit price.

Practically, an increase in the unit cost by a small margin and a constant quality and frequency of remakes often leads to increased overall profitability and a reduction in the disrupted clinical processes.

8. Quality Control Systems for E.max Outsourcing

The main pillar of the E.max outsourcing reliability is quality control (QC). In comparison to in-house production, with technicians able to make restorations on site, offshore E.max cases depend on a series of QC at various points, including fit and esthetics.

A multi-layer QC organization is widely used in professional laboratories:

(1) Design-Level QC

A review of CAD designs is done to check the margin integrity, minimum thickness, occlusal clearance, and anatomical precision before milling. This helps avoid mistakes that can not be rectified once they are made.

(2) Production-Level QC

The structuring process is checked by milling, crystallization, and layering to ensure the consistency of the structure. Any variation in sintering temperature or block location is recorded and rectified.

(3) Esthetic-Level QC

Shade, translucency, surface texture, and general harmony with the adjacent teeth are examined using standardized light. In the case of veneers, incisal translucency is also a delicate aspect and is confirmed at this point.

(4) Final Functional QC

Final restorations pass through fit evaluation, proximal contacts test, occlusal test, and last visual examination before shipments.

An organized checklist system makes every case traceable and deviations recorded, which reduces the remake rates and enhances client trust.

9. Communication Requirements to Avoid Remakes

The majority of E.max remakes are not due to technical restrictions but rather due to a lack of communication between the clinic and the outsourcing lab. It is essential to have clear and orderly submissions of cases to get predictable outcomes.

Important Communication Checklist of E.max Outsourcing:

(1) Clinical and Visual Information

- Intraoral photos (frontal, lateral, occlusal) of high resolution

- Even lighting to achieve shade and translucency

- The ability to see the margin clearly to design exactly

(2) Shade and Esthetic References

- Shade documented with photographic support

- Stump shade for veneers

- Brightness, translucency, or layering notes

(3) Case Instructions

- Clear guidelines on the aesthetic priorities and functional priorities

- Data on antagonistic dentition and occlusal scheme

- The patient-specific expectations and special requirements

Through this checklist, the laboratories can reduce the number of assumptions and be sure that the E.max restorations will be able to fulfill the esthetic and functional requirements on the first attempt, lessening turnaround time and the remakes.

10. Risks and Mitigation Strategies in E.max Outsourcing

E.max restorations outsourcing, though economical and scalable, has certain risks associated with it, which the laboratories and clinics must expect. Knowing these risks enables the prevention of risks and the seamless running of operations.

Key risks include:

(1) Mismatch of shade or aesthetic mismatch

E.max is very translucent; the slightest change in value, chroma, or incisal translucency can spoil the aesthetics. Mitigation: give quality photos, shade maps, and reference cases of each restoration.

(2) Fit and margin discrepancies

The open or overextended margins may be a result of thin margins and little preparation in the designs. Mitigation: explicit margin instructions and clear intraoral scans minimize the interpretation errors.

(3) Remake delays

Turnaround could be prolonged in shipping and remake processes when the responsibility is not clear. Mitigation: negotiate remake policies initially and ship tracked and insured to minimize uncertainty.

(4) Communication gaps

The effect of time zone differences and language barriers can slow down the clarification of cases. Mitigation: The structured templates, standardizing order forms, and the feedback cycles in batch help enhance clarity and minimize error.

These risks can be controlled by creating a standard workflow, clear communication channels, quality control checkpoints, and making E.max outsourcing predictable and reliable.

11. How to Choose the Right E.max Outsourcing Partner

It is imperative to choose a suitable E.max outsourcing partner. Not every laboratory has the experience, digital processes, or quality procedures to support high-esthetic anterior restorations regularly.

Take into consideration the following criteria:

- Experience with E.max crowns and veneers: Request checked case portfolios and examples of complicated anterior restorations. Find consistency of incisal translucency, margin fit, and surface finish.

- Material transparency: Make sure that the supplier has used authentic Ivoclar IPS e.max blocks, either Press or CAD, with batch traceability.

- Design and try-in support: The possibility to deliver digital wax-ups or physical try-ins implies high aesthetic control.

- Communication responsiveness: Speedy feedback that is well-organised minimises rework processes and makes sure that changes are made appropriately.

- Long-term partnership mindset: Customers or suppliers who fit your workflow and quality requirements will provide consistent and predictable outcomes in the long-term.

Selecting the appropriate partner makes outsourcing more about saving money than it is about becoming a part of your aesthetic group.

12. Who Should and Who Should Not Outsource E.max?

The outsourcing of E.max restorations is a good move, and knowing what practices will be most valuable and what might not will assist the laboratories in making the right decisions. Offshore E.max production does not benefit all the labs or clinics equally.

1) Who is well-suited for E.max outsourcing:

- High-volume laboratories: Labs that have a consistent demand for anterior crowns and veneers can use the outsourcing opportunity to boost throughput without necessarily investing in more milling machines and firing kilns.

- Digital-first clinics and labs: The current practices involving the use of intraoral scanners and CAD/CAM design have the advantage of simplified file transfer and predictability of results, which reduces the chance of interpretation error.

- Laboratories seeking aesthetic consistency: With outsourcing, skilled technicians with extensive experience in anterior esthetics are available, and this would help reduce the inconsistency in different cases and ensure high quality of results even with complex patients.

- Hybrid workflow operators: By mixing in-house production of part of the materials (e.g., zirconia) and outsourcing E.max, there is a balance of capacity, efficiency, and quality that can be achieved.

2) Who may not benefit from outsourcing:

- Ultra-low volume practices: Setups and shipping logistics might be expensive to the cost benefit of clinics that only receive occasional anterior cases.

- Same-day dentistry models: Activities involving chairside or immediate restorations cannot be based on international E.max outsourcing because of shipping and turnaround time.

- Clinics unwilling to standardize workflows: Good outsourcing involves good scans, photos, and prescription norms. Undocumented practices are vulnerable to being remade.

Assessing these aspects, laboratories and clinics will be able to determine whether E.max outsourcing meets their working model, patient expectations, and quality standards, and avoid unnecessary complications and guarantee the predictability of the results.

13. Frequently Asked Questions About E.max Outsourcing

The practice of outsourcing E.max restorations is bound to generate numerous practical and technical concerns. The questions below will be organized progressively to cover the most popular operational, esthetic and strategic issues, to make laboratories and clinics better aware of the process.

Q1: Do E.max veneers and crowns have remote anterior esthetic precision?

A: Yes, but it is a question of the quality of the information provided. There are also high-resolution intraoral photos, shade maps, and reference cases, which are necessary. Easy recording of incisal translucency, enamel layering preferences, and other adjacent tooth features enables the technicians to reproduce the esthetic subtleties with great precision.

Q2: Can E.max veneers be reliably manufactured through outsourcing in terms of thinness?

A: The vast majority of skilled laboratories are capable of regularly making veneers of 0.3-0.5 mm thickness, provided that there is an adequate preparation of the tooth, and that there is a good digital scan. Milling, crystallization, and glazing of thin veneers are sensitive processes, and chipping or distortion can occur, which is why it is important to specify the details of the margins and show supporting photos.

Q3: What happens to remakes when the restoration is not up to expectations?

A: Remake policies are characterized by reputable suppliers in advance. Accountability is usually based on the correctness of scans made, the completeness of shade data, and compliance with recommended design parameters. Open communication during the design review stage can be used to avoid misunderstanding and minimize the frequency of remakes.

Q4: Are outsourced E.max restorations comparable to the current dentition or past cases?

A: Yes, in case there is enough reference data. The lab can closely duplicate prior work by having digital scans of neighboring teeth, photographic shade guides, and detailed notes about translucency and surface texture. In the absence of this data, matching is not so predictable and can involve more try-ins.

Q5: Which outsourcing option should I be, Pressed or CAD E.max?

A: Both options are suitable. Often, veneers are being done with pressed E.max because of the natural layering and esthetic depth that can be created, and because CAD/CAM E.max can be reliably reproduced and be predictable in terms of crown thickness. The decision is made based on the complexity of the cases, aesthetic objectives, and laboratory abilities.

Q6: What can I do to ensure that the quality of outsourced E.max restorations is under control?

A: Control is ensured by the use of structured workflows, digital previews or try-ins, and feedback loops. The key factors that enable the laboratories to manage the functional and esthetic results include the comprehensive case instructions, tracking of the progress of the case at the critical QC steps, and the use of standard communication templates.

Q7: Are E.max case limitations to international outsourcing?

The key constraints are turnaround time and shipping logistics. It normally takes 3-5 days to complete the international shipping process, meaning that same-day or emergencies are not the right case to outsource. Also, full-mouth rehabilitations can be very complex, which means that local chairside adjustments are necessary that cannot be fully recorded remotely.

The answers to these questions will help the laboratories and clinics to define the needs of the operations, predict the difficulties, and streamline the cooperation with their E.max outsourcing partner.

14. Conclusion

Outsourcing E.max crowns and veneers is not only a cost-saving measure but a strategic move. With proper planning, partners, and established processes and communication, outsourcing enables the laboratory and clinics to increase production, keep the esthetic, and concentrate the internal resources on the patients and complicated cases.

To the laboratories or clinics intending to outsource or optimize E.max, partnering with a seasoned vendor like Bestodental may offer the desired operational effectiveness and aesthetic quality so that the work of the clinic or laboratory is consistent and predictable in all cases.