Outsourcing is a practice that is gaining popularity among dental practices and laboratories all over the world in an effort to cope with the rising demand for quality dental prosthetics. Of these, dentures that are made of acrylic are still one of the most popular and adaptable removable restorations, as they are relatively cheaper, flexible, and comfortable to the patient. Outsourcing the manufacture of acrylic dentures has turned out to be a viable and strategic option for clinics that would like to streamline their operations, lower the costs of production, as well as ensuring that the quality remains consistent.

The guide is a detailed outline of outsourcing Chinese acrylic dentures and offers all the details about the product, its basic knowledge, workflow, quality control, pricing, and selection of suppliers. And though you are a small clinic that needs to find a trustworthy production assistance or high-volume laboratory who need to optimize the available resources, this article will make you realize the range of opportunities, risks, and best practices that help to secure successful cooperation with overseas dental laboratories.

1. What Are Acrylic Dentures?

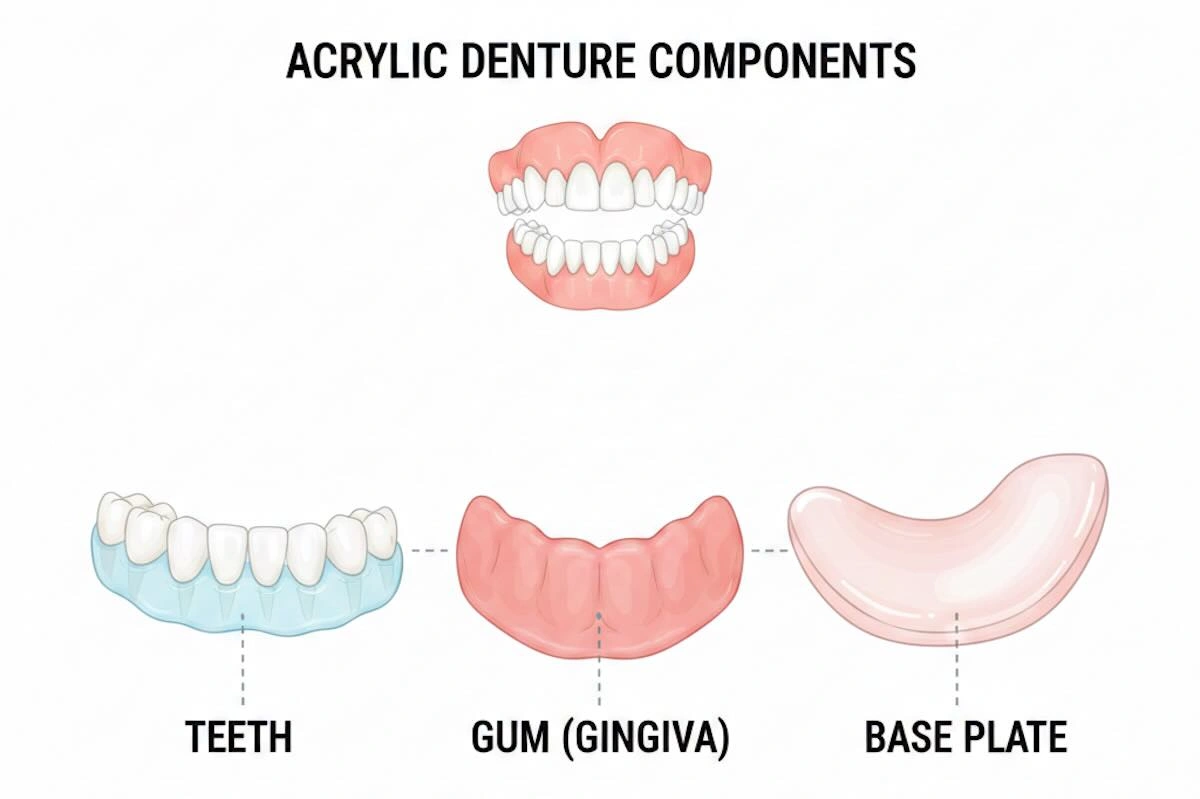

Dentures Acrylic dentures are removable dental prosthetic devices, mainly composed of polymethyl methacrylate (PMMA), also referred to as acrylic resin. They are created to serve as a replacement for the lost teeth and restore the oral functions, such as chewing, speaking, and preserving the facial appearance. The reason why acrylic dentures have gained popularity is that they are light, cheap, and comparatively easy to modify.

In the case of a dental laboratory or a dental clinic, the acrylic dentures usually consist of two parts: the denture base, which is placed on the gums of the patient, and the artificial teeth, which are fitted on the base. New acrylic dentures are customizable in terms of the shade of teeth, coloration of the gums, and how the teeth are aligned in the mouth, so that they look natural.

Compared to more complex forms of prosthetic like zirconia or metal-based restorations, acrylic dentures are completely made of polymer. This is why they are the best fit for patients who need temporary or full-time denture solutions, particularly when a fast and affordable turnaround is needed. The first step that any clinic has to take when it is thinking about outsourcing production is to understand its basic structure and functional purpose.

2. Why Are Acrylic Dentures Suitable for Outsourcing?

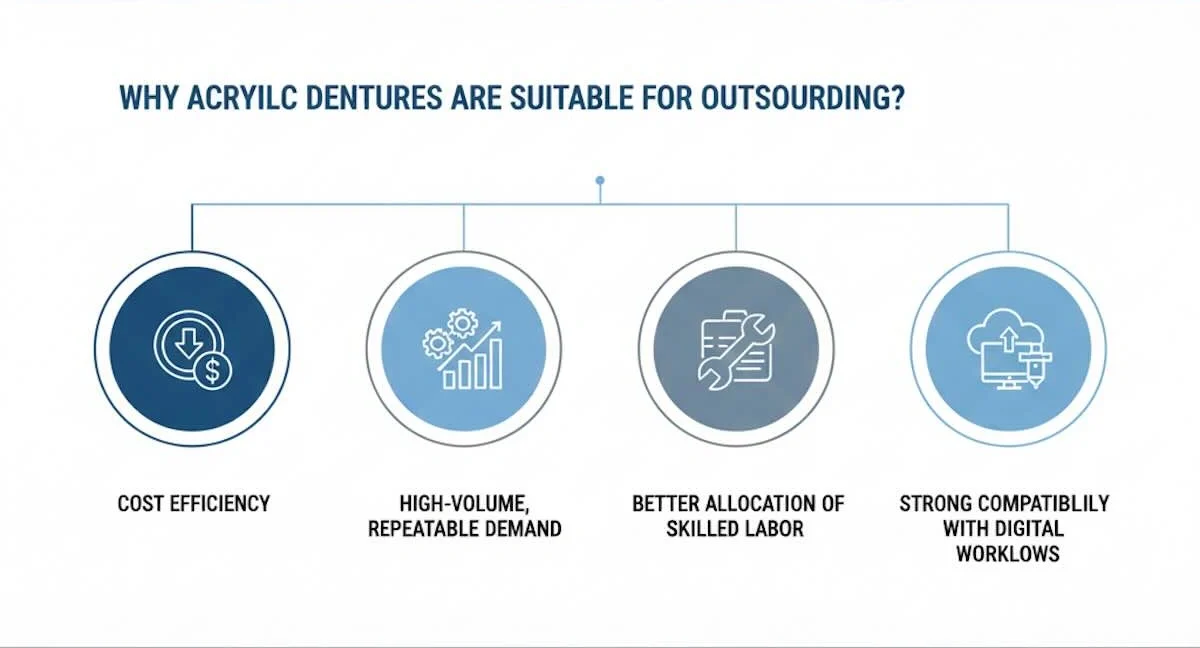

The acrylic dentures are the dentures that are particularly good to outsource because of a number of reasons. To begin with, they have standardized the production protocols, hence when a laboratory has your specification, they can make you the same quality of dentures time and time again. This consistency eliminates the possibility of mistakes and provides consistency in results between different cases.

Second, there is a moderate level of technical complexity in acrylic dentures. They do not need high-temperature sintering or complex milling, as do ceramic or metal-based restorations, and can be made reliably in large volumes.

Third, dental practices can put skilled in-house labor to work more effectively when it is outsourced. Subcontracting routine or a very large number of cases to an expert lab ensures that clinicians avoid wasting time in the denture-making process and instead concentrate on the patients.

Lastly, the savings on costs are high. By outsourcing to an efficient lab, overheads based on supplies, labour, and equipment are minimized. In the case of practices that deal with several cases every week, it may lead to significant financial and operational benefits.

3. Why Outsource Acrylic Dentures to China?

China has become a worldwide pioneer in the production of dental prosthetics, which is able to provide international clinics with a combination of low cost, technical capability, and quality service. It has several reasons as to why dental practices are increasingly sourcing acrylic dentures from Chinese suppliers:

- Low Cost: In China, the labour and cost of production are low compared to Europe, North America, or Australia. This enables it to compete without compromising on the quality of the materials, craftsmanship, and aesthetic outputs.

- Mature Supply Chains: Chinese labs that work in the international market have decades of experience with serving foreign markets. They have strong sourcing of materials, logistics, and quality control systems, with predictable production schedules and uniform denture quality.

- Technical Expertise: With the help of skilled technicians, a large volume of production and incorporation of digital processes, the labs can be international standards. Remote approvals are also done through digital design and verification tools, and minimise mistakes.

- Customization & Flexibility: Chinese labs can work with a great variety of specifications, including tooth shade matching and accurate bite alignment, as well as gum contouring. This increases their applicability to both routine and difficult patient cases.

- Quick and efficient logistics: The well-developed export routes and cooperation with other international courier companies can lead to shorter delivery times than anticipated, even to faraway markets. Other cases that can be carried out in the lab are the urgent cases that can be shipped in haste.

All in all, the Chinese outsourcing will offer international dental practices with the best combination of affordability, quality, and reliability. The choice of suppliers with experience enables clinics to comfortably outsource denture manufacturing and retain clinical quality, and enhance operational effectiveness.

4. What Can Be Outsourced: Understanding the Boundaries of Acrylic Denture Production

As far as the outsourcing of acrylic dentures is concerned, one should know how far he/she can delegate to another lab. The definite perception of these boundaries is one of the keys to the effective workflow as well as the maintenance of clinical standards and satisfaction among patients. Knowing the high probability of the actions being outsourced and the ones that should be done in-house will help the clinics to simplify their operations and quality control.

When outsourcing acrylic dentures, one should be aware of what can and cannot be outsourced:

1) Can Be Outsourced

- Full denture fabrication based on the presented impressions or digital scans

- Customization of the arrangement of teeth and the color of the gums

- Bite registration and occlusion adjustment

- Normal readjustments after delivery within set tolerances

These activities are quite appropriate to outsource since they are based on standard production procedures and are not urgent and patient-oriented clinical interventions. Labs that have skilled technicians would always provide quality results, thus saving the clinic personnel from concentrating on patients instead of fabrication.

2) Typically Not Outsourced

- First impressions of the patient (have to be made at the place)

- Last in-mouth minor adjustment

- Repairs that are emergency in nature

These are the aspects that should be maintained inside the organisation since they imply direct patient contact or emergency changes that have to be addressed by the clinical staff as soon as possible. An attempt to outsource such steps may jeopardize the fit, function, or patient experience.

Delineation of these boundaries makes sure that the clinics have control over the clinical outcomes and employ the external production capabilities. It also sets the communication, delivery, and responsibility expectations.

5. Step-by-Step Workflow: How to Outsource Acrylic Dentures Effectively

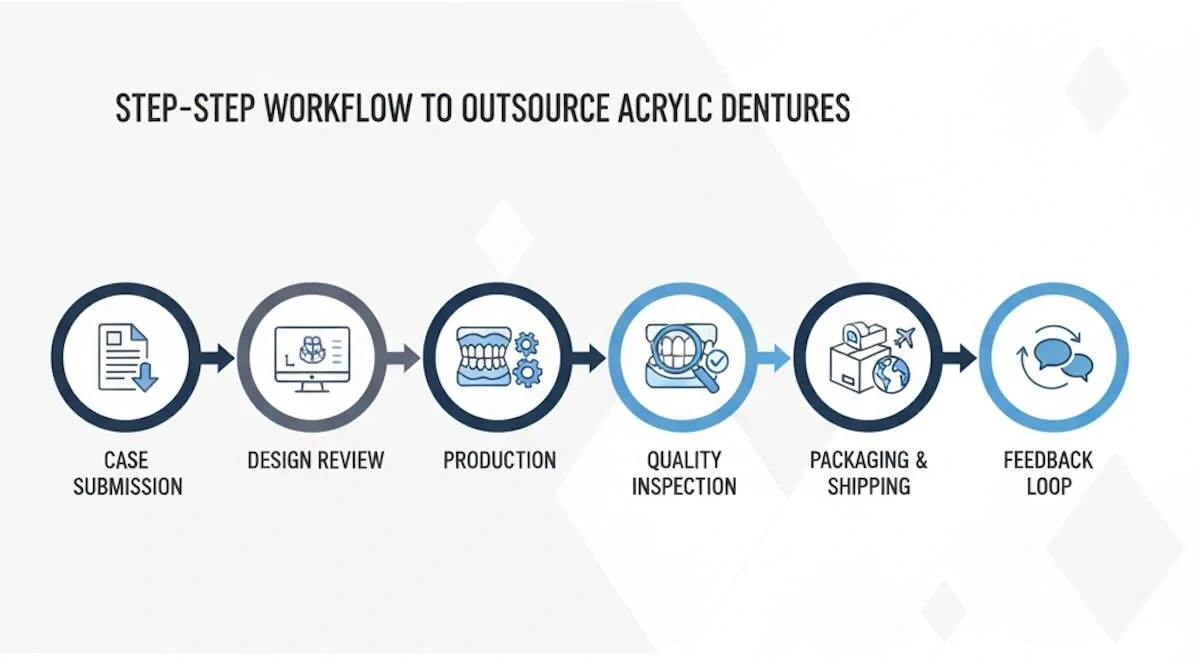

A clear workflow on outsourcing is necessary in terms of predictability, minimizing errors, and upholding high clinical standards. The workflow of acrylic dentures is a combination of accuracy and effective communication between the clinic and the outsourcing laboratory. In this process, the clinics can outsource in a step-by-step procedure that is summarized as follows:

Step 1: Case Submission

Submit patient impressions, computer-generated scans, or ready-made denture models to the lab. Record specifications in detail: tooth type, shade, gum coloration, bite registration, and any other special instructions (e.g., aesthetics, previous occlusion issues, or functional requirements). This stage will have proper and complete records that will prevent delays and make sure that the lab will be able to replicate the needs of the patient correctly.

Step 2: Design Review

The lab examines the data provided and establishes the choice of material, position of bites, and positions of teeth. Other, more advanced laboratories give a preview in digital form or as wax-ups of the final product to validate before it is produced, where a clinic can confirm the look and bite. Any differences or necessary changes at this point can be resolved without impacting production schedules.

Step 3: Production

The denture base is made by skilled technicians, the teeth are positioned, implanted, polished, and internal quality control is done. In modern laboratories, CAD/CAM workflows, digital articulators, and precision milling are usually combined to achieve increased fit and consistency. In the case of acrylic dentures, correct polymerization and controlled curing are essential to prevent deformation or color change.

Step 4: Quality Inspection

The final product is checked by a special QC team on the basis of occlusion, tooth arrangement, color matching, and general aesthetics. The expensive laboratories can send pictures or 3D images of the denture to be verified remotely, so the clinic is free to accept the denture and ship it. There are also some laboratories that carry out bite simulations in order to identify any functional problems at an early stage.

Step 5: Packaging & Shipping

Complete dentures are packed with care in order to avoid damage during transit, and some need desiccants or protective molds. The international deliveries involve traceability, insurance, and adherence to customs. Shipping updates and estimation of the delivery window are often offered by labs in order to plan the in-clinic scheduling.

Step 6: Feedback Loop & Post-Delivery Support

Upon receipt, the clinic checks the fit, bite, and looks. Fewer changes, like occlusals or minor repositioning, can be done internally. In case of bigger corrections, effective communication with the lab will result in the right corrections to the active or pending orders. It would help to sustain this feedback loop, which enhances accuracy and increases collaboration over time.

Through this workflow, the clinics will be able to outsource the production of acrylic dentures without any concerns regarding clinical quality and enjoy the benefits of external labs, scalability, and cost-efficiency. It brings about transparency in operation, reduction of remakes, and also brings about a comfortable, professional relationship between the clinic and the supplier.

6. Turnaround Time: Managing Delivery Expectations for Outsourced Acrylic Dentures

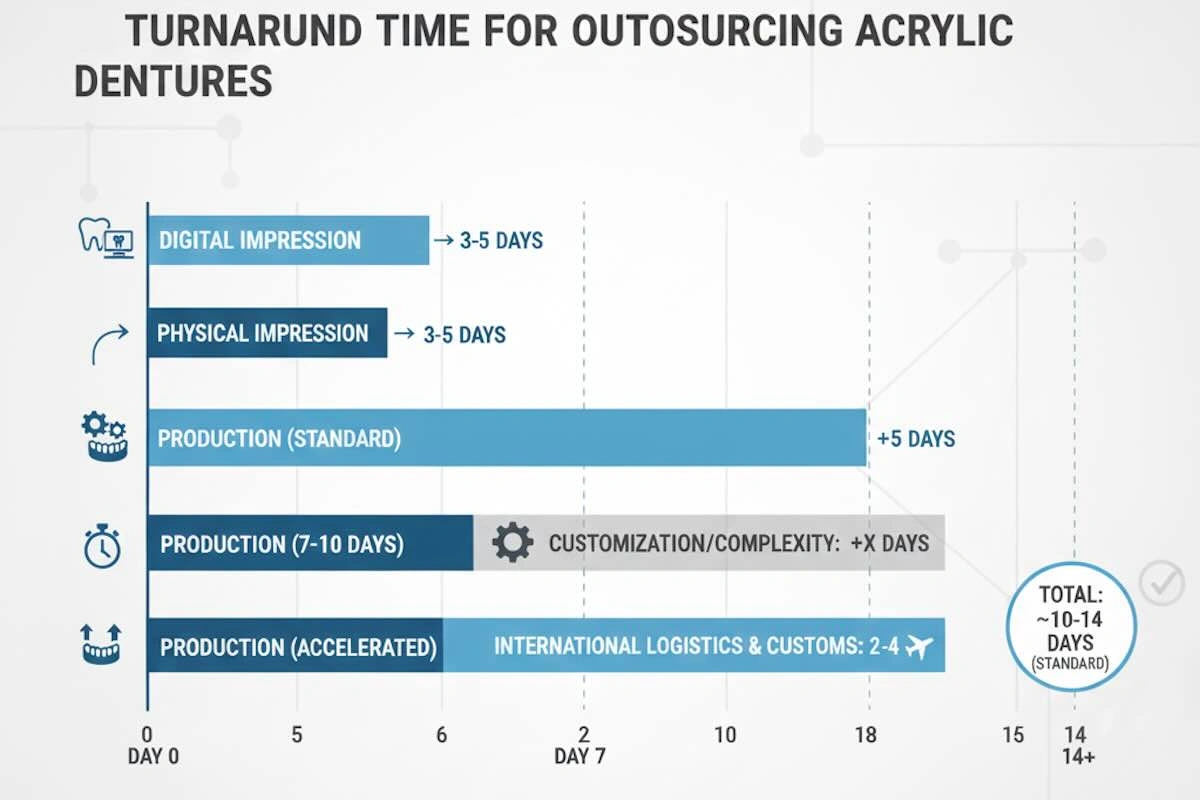

Outsourced acrylic dentures have a turnaround time that is determined by the complexity of the case, the volume of the order, and the destination of the shipping. Production of standard full dentures normally takes 7-10 business days, excluding the time needed to transport them. Multiple variables may influence delivery schedules:

- Digital and physical impressions: Digital scans are usually quicker to make than physical models, which might need further manipulation and verification.

- Customization needs: Preparation time: Unique tooth coloring, bite registration, or gingival contouring are more complex requirements that can increase fabrication time.

- Shipping and clearance: The shipping time depends on the courier, country of destination, and regulatory checks.

Predefined production schedules can be used with high-volume customers or repetitive orders, which helps to cut down lead times and provide a consistent timeframe of delivery. Expedited services of urgent cases are also available in many Chinese laboratories, hence outsourcing is a possible solution even to urgent patient treatment. Timely arrangements and coordination with the laboratory assist clinics to have predictable schedules and prevent disruption of its workflow.

7. Pricing Guide: Understanding the Full Cost of Outsourcing Acrylic Dentures

Price, when outsourcing acrylic dentures, is not an amount of money per unit. The overall cost depends on a variety of factors that must be taken into account to make a decision and be efficient in their operations:

| Pricing Factor | Description | Practical Consideration |

| Material Selection | Standard PMMA vs. premium/high-impact acrylics | Choose material based on durability and aesthetics; premium materials cost more but improve patient satisfaction |

| Customization Level | Shade matching, gum anatomy, bite registration | Higher customization improves fit and aesthetics, but increases production time and cost |

| Order Volume | Single-unit vs. bulk orders | Bulk orders reduce per-unit cost; plan batch orders for recurring cases |

| Shipping & Logistics | Courier, insurance, customs | Include shipping and customs fees; track shipments to avoid delays |

| Payment & Contract Terms | Prepayment, installment, credit account | Manage cash flow and reduce financial risk by understanding payment requirements |

| Additional Services | Expedited orders, digital previews, repeat modifications | Factor in extra fees for urgent or specialized services |

| Supplier Reliability & Warranty | Quality guarantee, return/rework policy | Reliable labs may have a higher upfront cost, but minimize remakes and hidden expenses |

A combination of these aspects will enable the clinics to estimate the actual cost-effectiveness of outsourcing. In addition to the unit prices, labor, equipment wear, and tie-up of resources in the house can be saved through outsourcing, and in most cases, 30-50 percent of the operational costs can be saved with no variation in quality.

8. Quality Control Systems: Ensuring Consistent and Reliable Acrylic Dentures

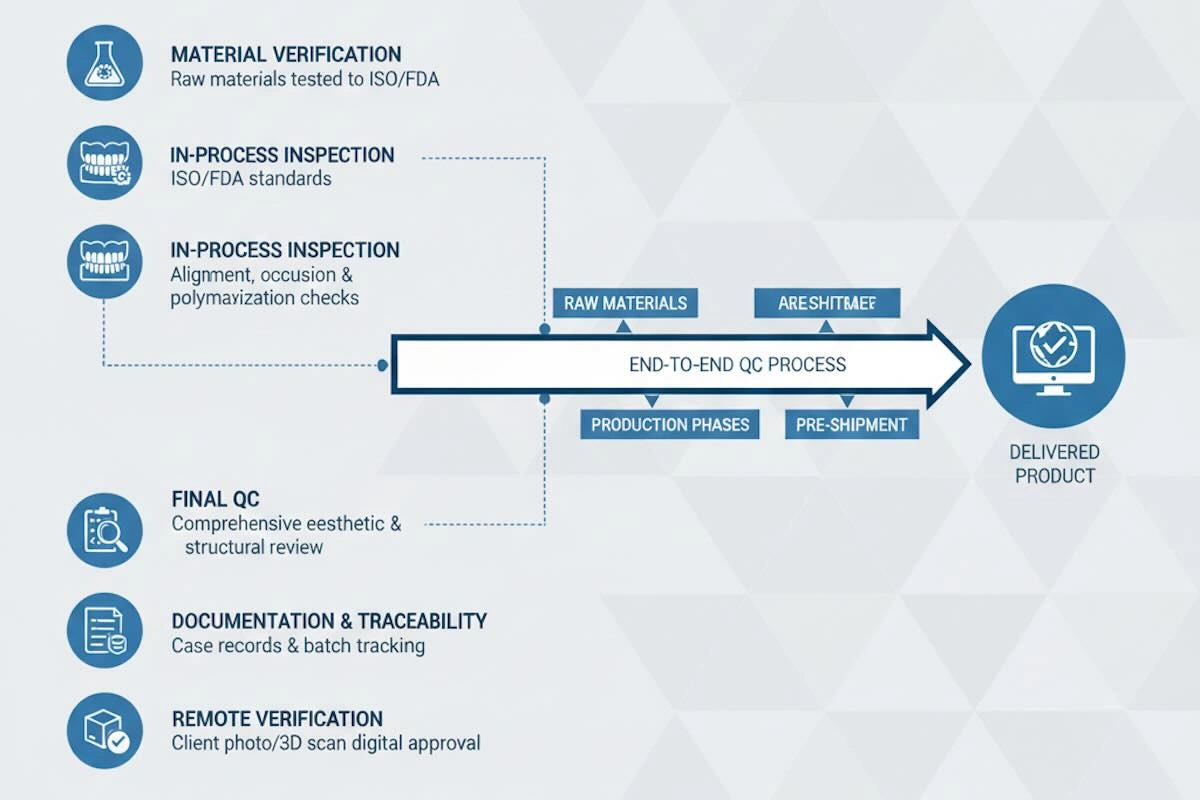

Quality control (QC) is also very important in outsourcing acrylic dentures since it has a direct impact on clinical outcomes and patient satisfaction. Top laboratories use several levels of QC to make sure that every denture is up to international standards:

(1) Material Verification

Every acrylic, tooth, and auxiliary material is verified to be within the ISO or FDA standards and is biocompatible, durable, and safe to the patient.

(2) In-Process Inspection

Technicians measure tooth alignment, occlusion, and polymerization during the fabrication process, and this enables mistakes to be corrected early and fewer remakes to be done.

(3) Final QC

Every denture is carefully assessed in the areas of fit, occlusion, aesthetics, and structural integrity before shipping to ensure a uniform quality delivery.

(4) Documentation & Traceability

These are among the most common security vulnerabilities in the system. Each case is documented in detail, which allows one to hold people responsible and provide a leader with references to make any changes in case of necessity.

(5) Remote Verification

Most labs offer photos, 3D scanning, or digital quality control reports, enabling clinics to review and accept quality without being on-site.

With this type of QC, clinics are able to entrust their acrylic denture manufacturing to a vendor without showing a lot of concern regarding the standards and the risk to the clinical.

9. Communication Requirements: Key Steps to Avoid Remakes

Outsourcing acrylic dentures requires effective communication to have a direct impact on the fit, aesthetics, and patient satisfaction. These are the most important points that should be undertaken by clinics to reduce remakes:

- True Impressions or Software Scans: Use quality impressions or accurate scans of digital impressions to make sure that the lab is able to reproduce the oral anatomy of the patient.

- Detailed Specifications: Add detailed bite registration, tooth shade, gum contouring, and special instructions like previous denture alignment or unusual occlusiveness.

- Consistent Feedback: Get continuous communication with the lab, reviewing prototypes or photos where possible, and responding to any questions or discrepancies in time.

These practices minimize errors, reduce the time of production, and improve the dependability of outsourced production of acrylic dentures fabrication, which guarantees predictable results in the case of patients.

10. Risks and Mitigation: Managing Challenges in Acrylic Denture Outsourcing

There are great benefits of outsourcing acrylic dentures, but the clinics should be aware of possible risks and what they should do to prevent them. Adequate risk management is known to provide expected results, remake minimization, and protect patient satisfaction.

| Risk | Description | Mitigation Strategy |

| Miscommunication | Incorrect or incomplete instructions can lead to denture fit or aesthetic issues | Provide detailed case documentation, including impressions, bite registration, shade, and special instructions; confirm understanding with the lab |

| Production or Shipping Delays | International transit, customs, or lab backlog may postpone delivery | Plan orders in advance, use reliable logistics providers, and request estimated timelines; consider labs offering expedited services |

| Material or Color Mismatches | An incorrect acrylic or tooth shade may compromise aesthetics | Specify materials and shades clearly; request samples or digital/physical previews for verification |

| Lab Quality & Compliance | Inconsistent quality or lack of certifications increases the risk of remakes | Choose labs with ISO/FDA certification, proven experience, and established international workflows |

| First-Time Orders | New suppliers may have untested processes | Begin with pilot orders to validate workflow and quality before committing to large batches |

Although the clinics can identify potential risks and these mitigation measures, the clinics have an opportunity to outsource acrylic dentures with certainty that they would regulate the quality, time, and clinical results.

11. How to Choose the Right Supplier: Ensuring Reliability and Quality

One of the most essential steps to outsource the acrylic dentures is a definite choice of a supplier, as the final point that directly determines the quality of the products, as well as the turnaround time and the satisfaction of the patients. To reach an excellent cooperation, clinics should take into consideration the possible partners in numerous dimensions:

(1) International Customer Experiences

The suppliers, who are aware of the needs overseas, know shipping policies, quality expectations, and standards of communication, decreasing the possibility of delays or mistakes.

(2) Online Workflow Functionality

Digital scan laboratories, remote designing approvals, and electronic case management make the process easier and enable proper verification without necessarily visiting the lab.

(3) Certifications and Compliance

The certification by ISO or FDA proves the level of compliance with global quality and safety standards, which gives assurance of the quality of materials and production methods.

(4) Open Pricing and Quality Control

The precise cost structure and recorded quality control mechanisms reduce hidden expenses and avoid misunderstandings.

(5) Responsiveness and Communication

ORNC Services should respond in time, provide updates on progress, and be ready to clarify requirements,s and this would help smooth the handling of the case and limit the chances of remake.

In the case of acrylic dentures, Bestodental is a representation of these attributes. They feel competent to provide high-quality, consistent dentures manufactured on a large scale, with decades of experience and ISO-certified plants, and with the necessary experience in global logistics.

12. Who Should Outsource and Who Should Not: Identifying the Right Fit

The choice of whether to outsource acrylic dentures will need a clear comprehension of the operational requirements, the complexity of a case, and patient expectations. Outside production does not have the same effect on all clinics or laboratories.

1) Suitable for Outsourcing

- Clinics that have a large number of patients and require production that is predictable and scalable

- Labs without specialized denture technicians or state of the art equipment

- Practices that strive to cut costs without lowering in-house labor costs

Such clinics are able to be efficient, save costs, and maintain quality through the application of external expertise. The outsourcing enables the staff to concentrate on patient care and other value-added activities, but at the same time, deliver dentures on time.

2) Not Suitable for Outsourcing

- Cases where adjustments must be made, or emergency repairs are necessary on the same day

- The clinics focus on the real control of every piece of fabrication

- Patients with complex problems of the mouth that require highly intensive, individualized efforts

In these cases, the in-house production is better to be used to have direct control, be able to respond quickly, and meet highly personalized clinical demands.

Finding the right and the wrong cases is important to enable dental professionals to reach effective outsourcing decisions, to synchronize the work operational strategy with the clinical capacity, and to maximize the patient outcomes and the working efficiency.

13. Outsourcing Acrylic Denture FAQs: Expert Answers for Clinics

Regarding outsourcing acrylic dentures, clinics tend to ask certain questions regarding the workflow, quality, and logistics. The frequently asked questions listed below aim to resolve the most widespread issues and offer guidance on informed decision-making:

Q1: Are digital impressions applicable to outsourcing?

Yes. STL files are accepted, and other digital formats are accepted by many reputable labs in China, allowing completely digital workflows. Online impressions are more accurate, faster, and the verification can be done remotely before production.

Q2: What is the minimum order quantity?

Outsourcing is a possibility for small clinics because most labs receive individual case orders. Nevertheless, large or repeat orders tend to be associated with lower unit costs and schedule priority.

Q3: What is the way of ensuring material safety?

ISO/FDA-compliant PMMA and teeth materials are used by the major suppliers. Any material is tested in terms of biocompatibility, color stability, and mechanical strength to make the prosthetic safe and durable.

Q4: What is the management of denture shades and aesthetics?

Labs reference teeth and gingival shades with the help of standardized guides (e.g., VITA) or photos or patient-specific references. Natural translucency and texture can also be reproduced by experienced technicians to achieve the best aesthetics.

Q5: What should happen in case of poor fit of denture?

Less complex modifications, like occlusions or minor positioning of teeth, can be done in-house. In the event of major fit or functional problems, the majority of the labs do re-fabrication, as an option, with the help of digital verification or follow-up cases.

These FAQs present some of the major factors that can guide the clinics in outsourcing the acrylic dentures to control the quality and workflow, as well as patient satisfaction.

14. Conclusion

The possibility of using China in the outsourcing of acrylic dentures gives dental clinics and laboratories an economical method of delivering high-quality services at the best operational efficiency. Practices may minimize errors and remakes by comprehending the production workflow, delivering precise impressions or digital scans, establishing clear specifications, and ensuring consistent communication, which will result in predictable outcomes on behalf of their patients. This is a framework that enables the clinics to concentrate on patients and use outside professional services to make common dentures.

Bestodental is one of the prospective partners because of its decades of experience, facilities quality-certified by ISO, and its multi-layered quality control and international responsiveness. Their technical experience, high-volume production, and loyalty to cooperation with clients guarantee the high level of reliability of their acrylic dentures, being customized and able to meet the needs of the clinic. The collaboration with Bestodental allows clinics to optimize their production, control their expenses, and provide professional and consistent outcomes that can promote patient satisfaction.